We service it all!

smarter, safer and more efficient.

Facility Automation

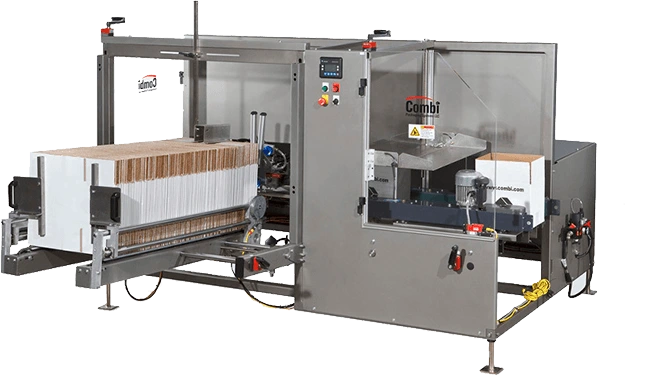

Packaging line experts – equipment, parts, service and packaging

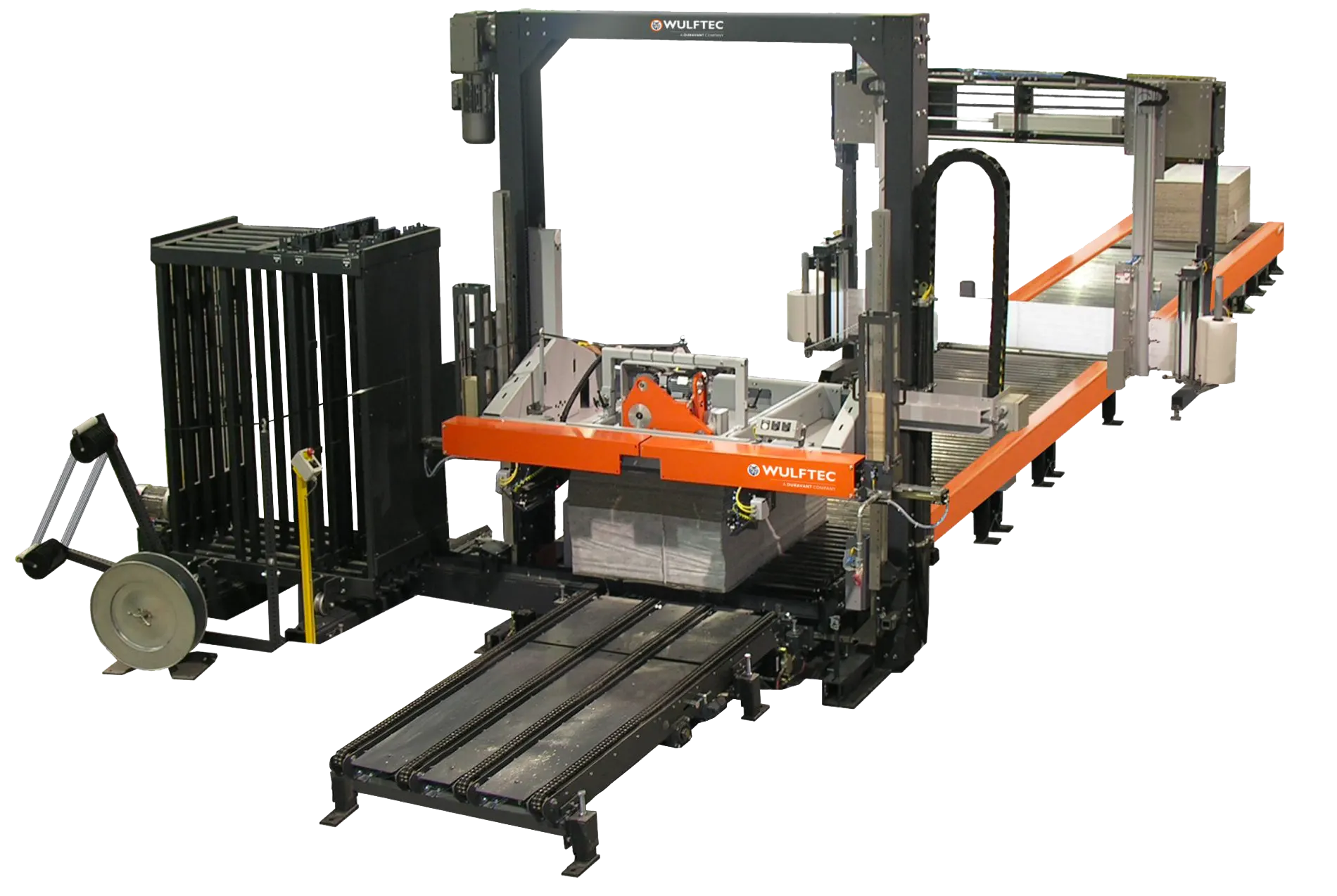

- Stretch Wrappers

- Tray Formers

- Strappers

- Shrink Wrappers

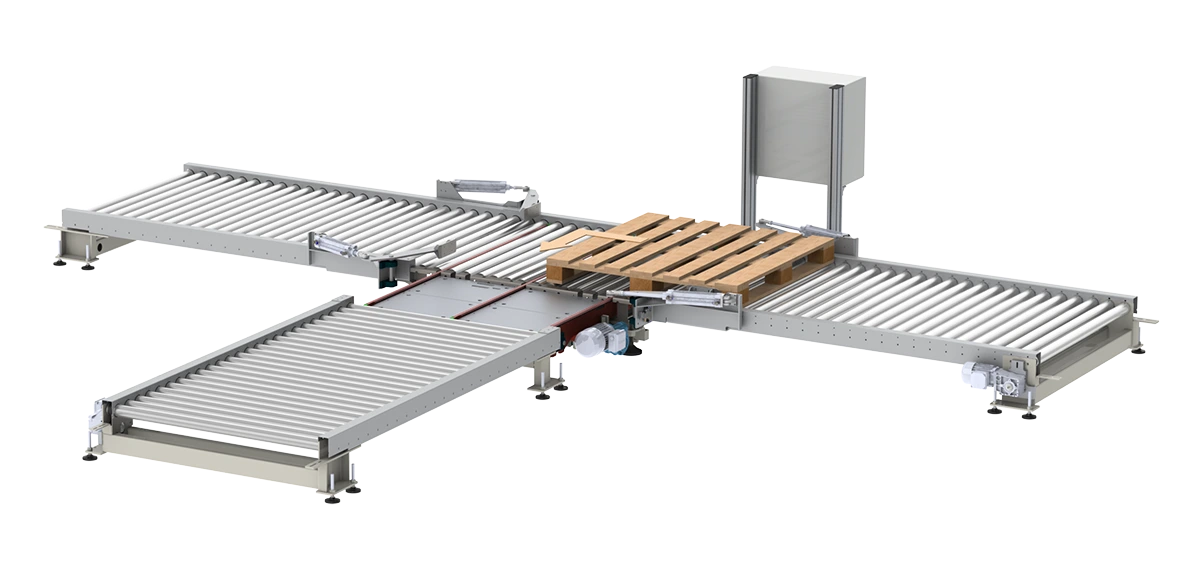

- Conveyor Systems

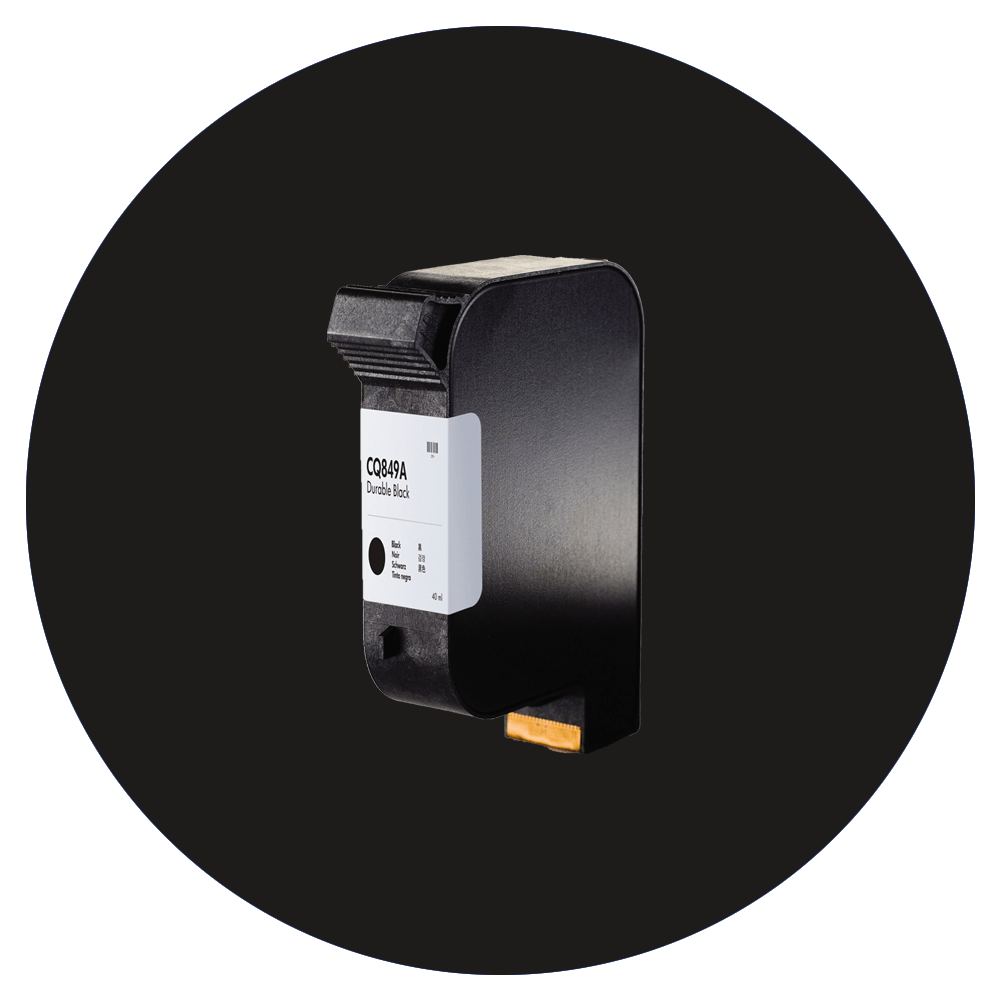

- Ink Jet Systems

- Case Erectors

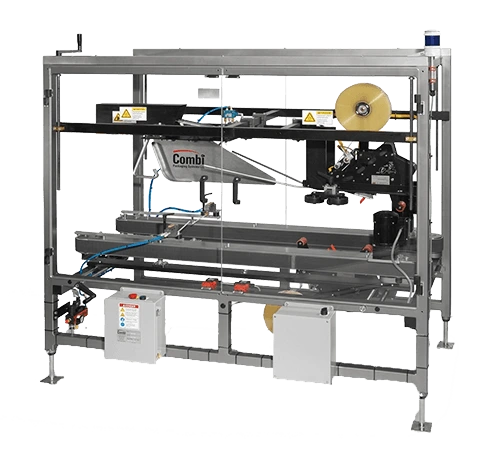

- Case Sealers

- Palletizing Systems

- Bagging Systems

- Scanning & Vision Systems

- #1 Wulftec service house

- If we can’t fix it, you don’t pay

- Service contact monitored perpetually

- Installation & service anywhere in the country

Installation & Relocation

Your equipment matters

- We’ll go anywhere in the country – give us an address!

- Tear down and set up of equipment

- We can handle equipment transportation

- Perfect time for PM & routine service work

- First class installations, clean and professional

- Quick turnaround times

Equipment performance

audits

Improved Efficiency

- Load containment – we can show you how to double or even triple your load containment force

- Wrap time evaluations – often we can increase efficiency by 50% or more

- Film breaks? It’s often not the machine but the film itself.

- Remote auditing options – track every pallet wrapped and see deviations in performance. Know when a problem arises or when something changes before it affects your throughput.

Scheduled

Maintenance

Maximize equipment life

It’s time for a tune up

- Custom service plans based on machine usage and production importance

- Detailed work orders and service reports

- Face to face discussions about what we find and do during scheduled maintenance

- Stretch wrappers, strapping equipment, case erectors, tape machines & more

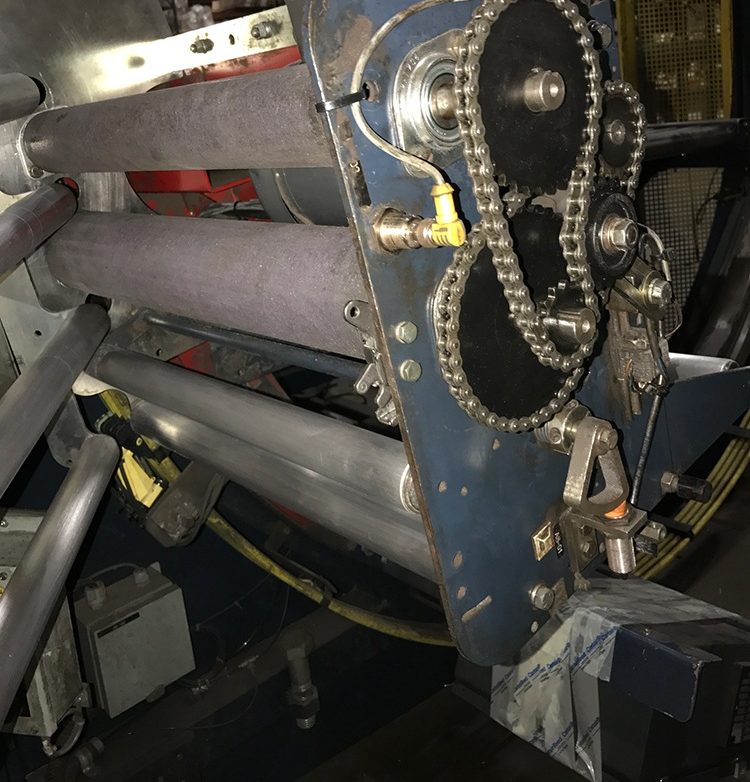

Stretch wrap equipment retrofits & upgrades

Improve your process

- Film Roping Retrofit

- New Carriage Upgrade

Consider a 30″ film carriage to wrap quicker! - Dual Tension Upgrade to help wrap light & unstable pallets

- Wrap Speed Upgrades

- Replace cut & worn out pre-stretch rollers with cut-proof lifetime warranty rollers

- Add Load Pop-Up systems to your conveyor wrap zone to capture and wrap the entire pallet!

Experience?

WE’VE GOT THAT.

- 100+ systems installed yearly

- 1000+ machines serviced yearly

- From concept to installation, we handle the entire job in-house.

Looking for packaging?

STOP!

Need parts? Need service?

Not sure what you need?

We’ll get you running again 👍

MAKE SOME MONEY / SAVE SOME MONEY

BUY AND SELL USED EQUIPMENT

IN HOUSE REFURBISHING – CONSIGNMENT PROGRAMS

- Pre-owned stretch wrap machines

- Pre-owned shrink wrap machines

- Pre-owned tape machines

- Pre-owned strapping equipment

- Pre-owned conveyor systems

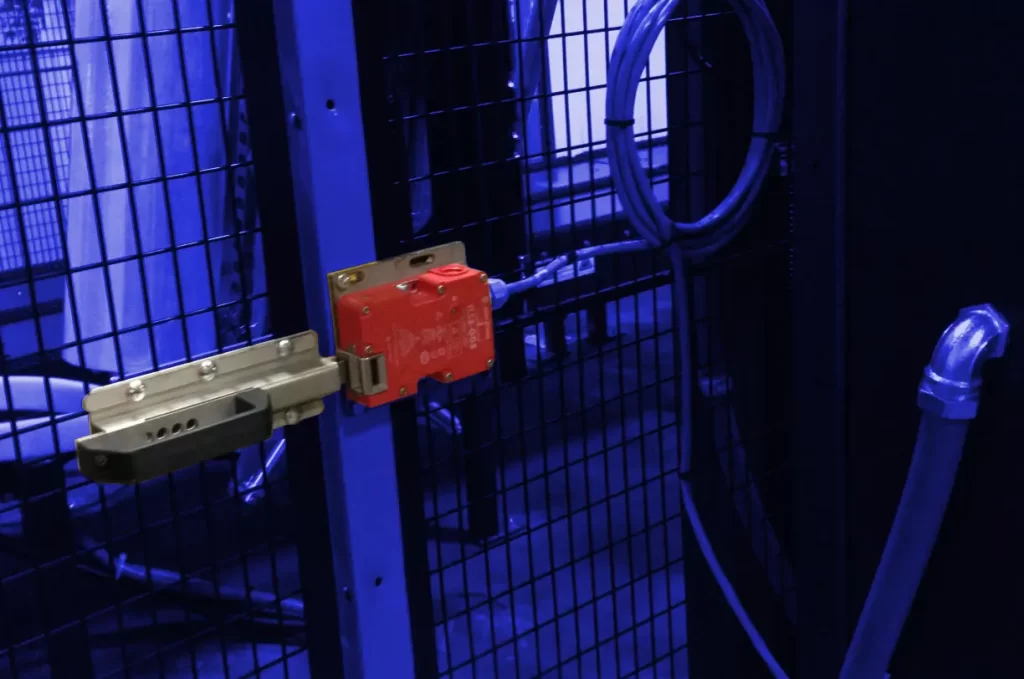

SAFETY STARTS HERE

PROTECT YOUR PEOPLE

- Light curtain installations

- Photo eye protection for both people & equipment

- Area laser scanners

- Pressure activated safety mats for all types of equipment

- Safety Fencing

- Safety Guarding

- Safety Beacons & Audible Alarms

- Lock Out Tag Out Training

- E-Stop Additions

We offer a range of intrusion detection solutions which allow for an open flow of people or product while providing highly accurate intrusion detection to mitigate the risk of injury, death or damaged equipment. From advanced safety light curtains to photo eye configurations and laser based systems – SWS can integrate any of these with your existing packaging line to provide the highest degree of intrusion detection possible.

Warehouses and production environments can be very noisy at times and it is crucial that one is aware of their surroundings when carrying out tasks in the proximity of running equipment. Integrating audible alarms into your packaging line can provide valuable awareness to workers within the area while visual alarm light systems can inform hearing impaired individuals and provide workers not in the immediate vicinity with cues as to the operating state of the packaging line and inform their decisions.

Safety fencing is possibly the simplest, most practical and most reliable safety solution for a packaging line – with sections coming in many different sizes and shapes, allowing them to be placed in a wide array of configurations around any piece of your packaging line. While sensors are a powerful safety solution where an open flow of product or people is needed, fencing is a very desirable solution at any other part of the line.

Even with a fully automatic system, direct access to the machine is often necessary. Quick stop gate latches for safety fencing configurations are an essential piece of the puzzle. It is one thing to place fencing around your equipment, preventing collisions with equipment and other accidents, but it is another thing entirely to prevent human error.

Quick stop safety mats are extremely durable floor mounted sensors that operate as an emergency stop switch.

Drive a lift right over them and load the wrapper with confidence. If anything steps, rolls or falls into the wrap zone during the the wrapping sequence the machine will stop.

Did you know?

- SWS has the largest documented history of installations, retrofits and startups of packaging equipment in the entire industry. You will not find another company with as many documented installations right on their website.

- SWS makes over 1,500 packaging equipment service calls every year. More than 25% of those are multiple day service calls and or multi day installations and retrofits.

- SWS installs all the equipment solutions we provide. We do not sub out our installations. No pointing fingers at others as we handle the job personally from concept through installation and into service.

- SWS service coordinators are monitoring our service contact address and contact forms with less than 10 minute response times.

- SWS partners with approximately 40 other packaging houses and integrators to help provide equipment and installation of that equipment. That is right, we have done work 100s of times for those who many would consider our competitors. When you work with us you can trust our integrity.

- SWS has installed equipment in more than 40 states.

- SWS services all packaging equipment: stretch wrappers, strappers, case erectors, carton sealers, shrink systems, pallet inverters and much more.

- SWS has the ability to retrofit all manner of equipment with programming & controls – performed in house.