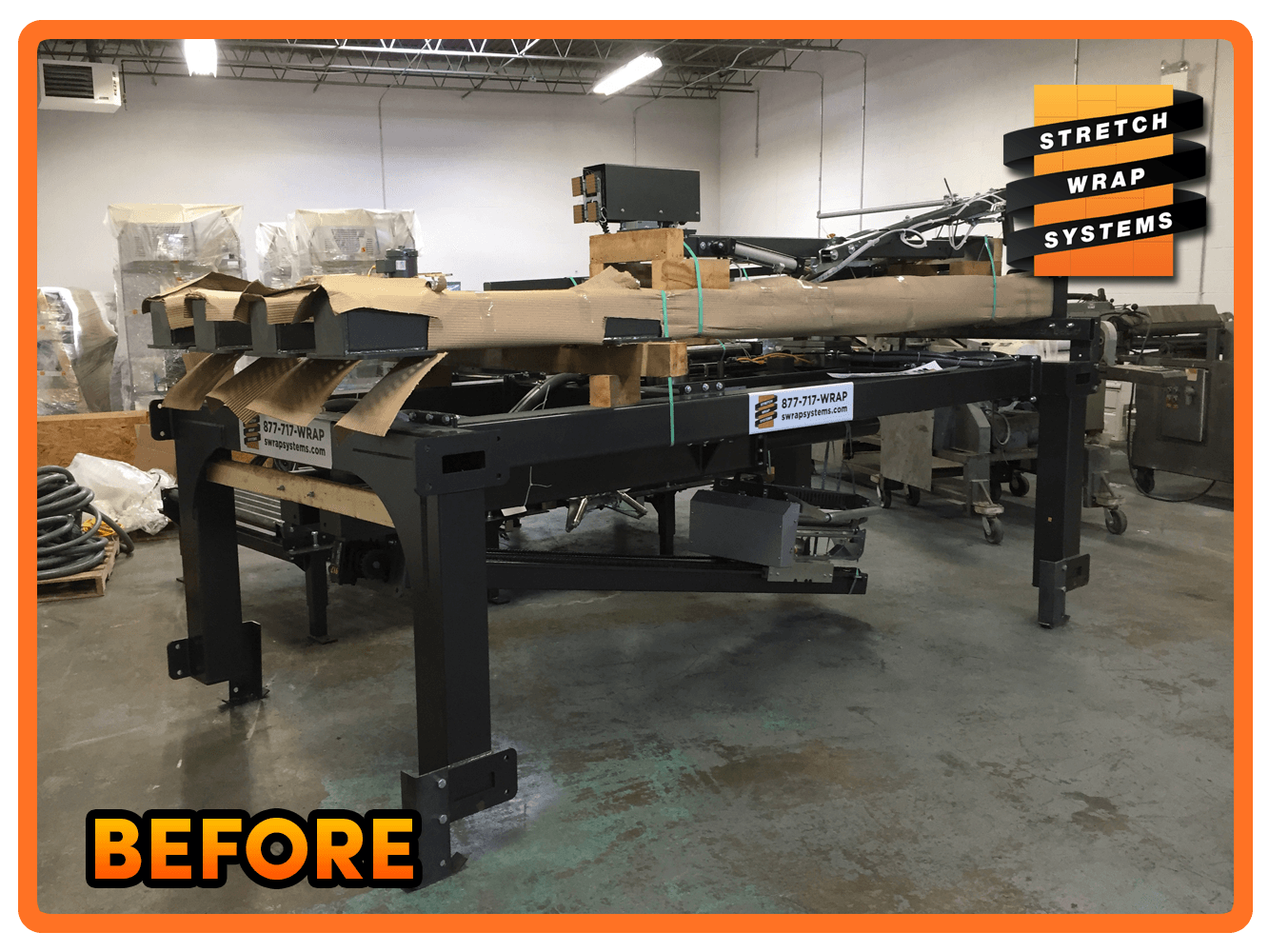

SWS tech John Koehler was on location at a customers facility in York, PA for a conveyor retrofit. Cut a 30′ Gravity Section down to 20′ Added PLC I/0 and manual controls Programmed in all logic NO WIRES HANGING!

Portfolio Categories: service

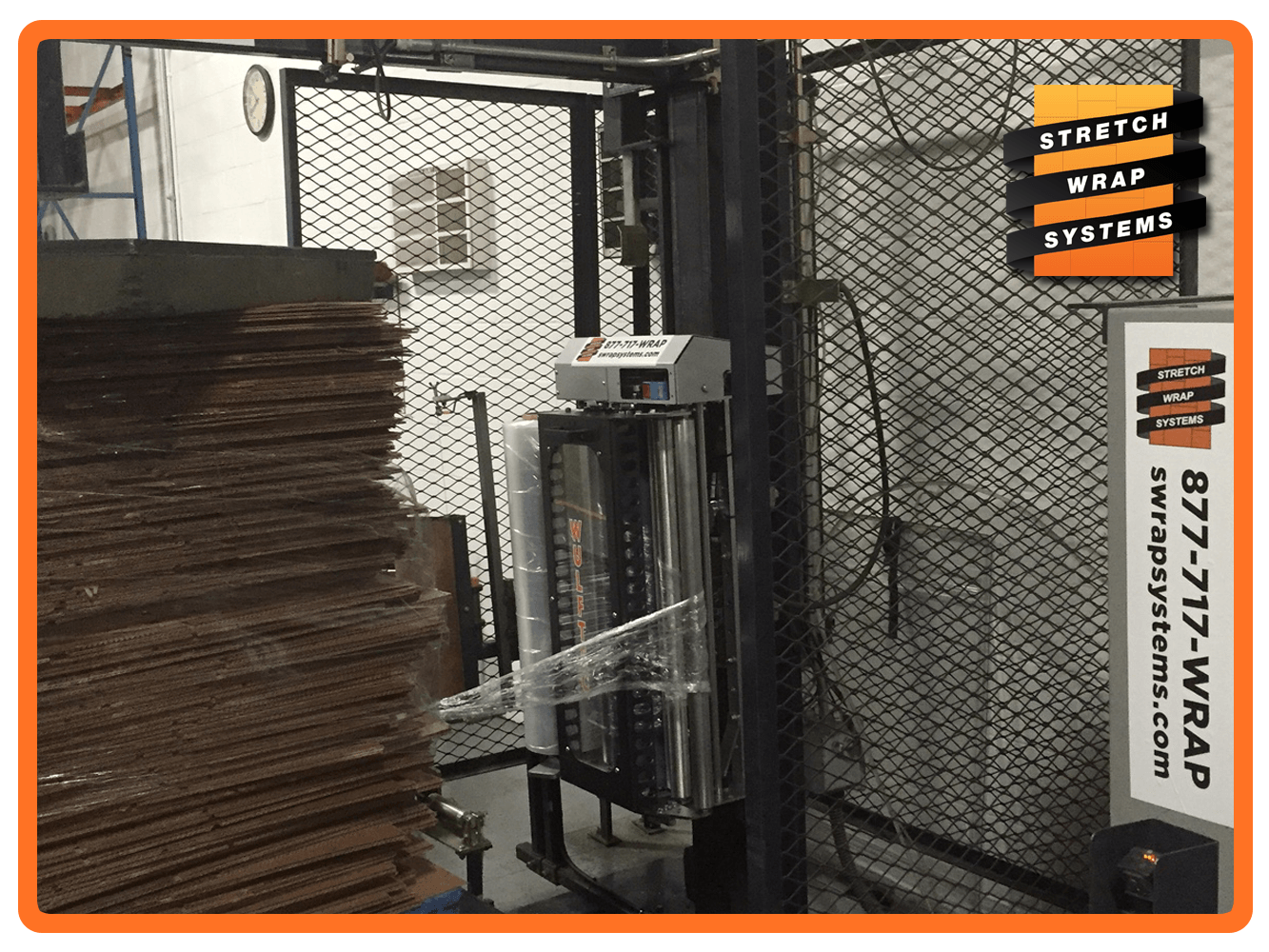

Northeastern PA – 10/18/16

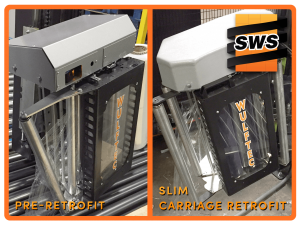

SWS technician Andrew retrofit this machine with a slim profile 20″ film carriage. The slim design increases the wrap zone diameter, accommodating slightly oversized pallets. Freezer application Technician: Andrew

Hazelton, PA – 10/21/16

SWS technicians Andrew and Matt converted this WHP Stretch Wrapper into a Split Base Turntable Stretch Wrapper and integrated a scale for the customer before installing it. WHP to split base conversion Technicians: Andrew & Matt

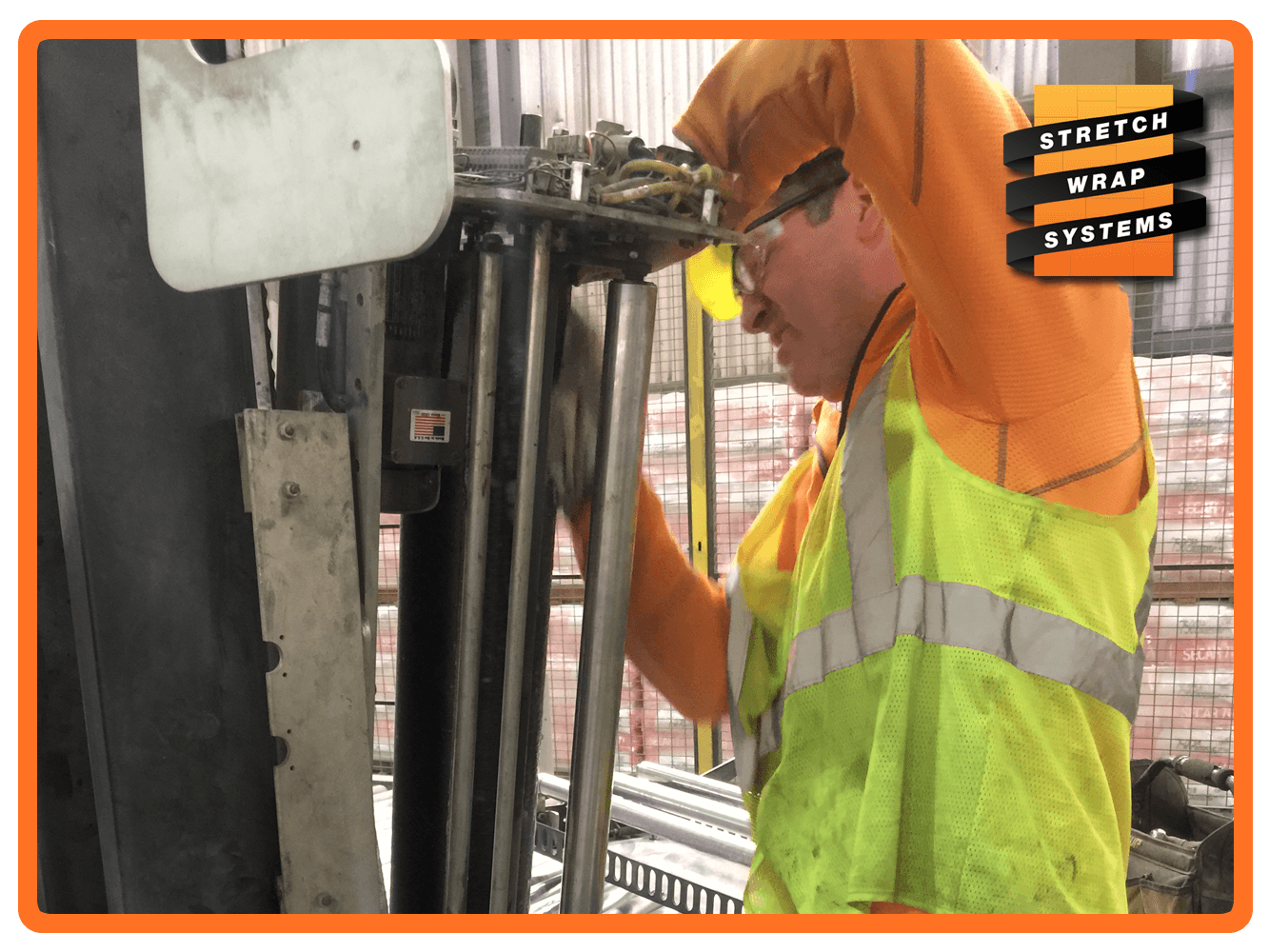

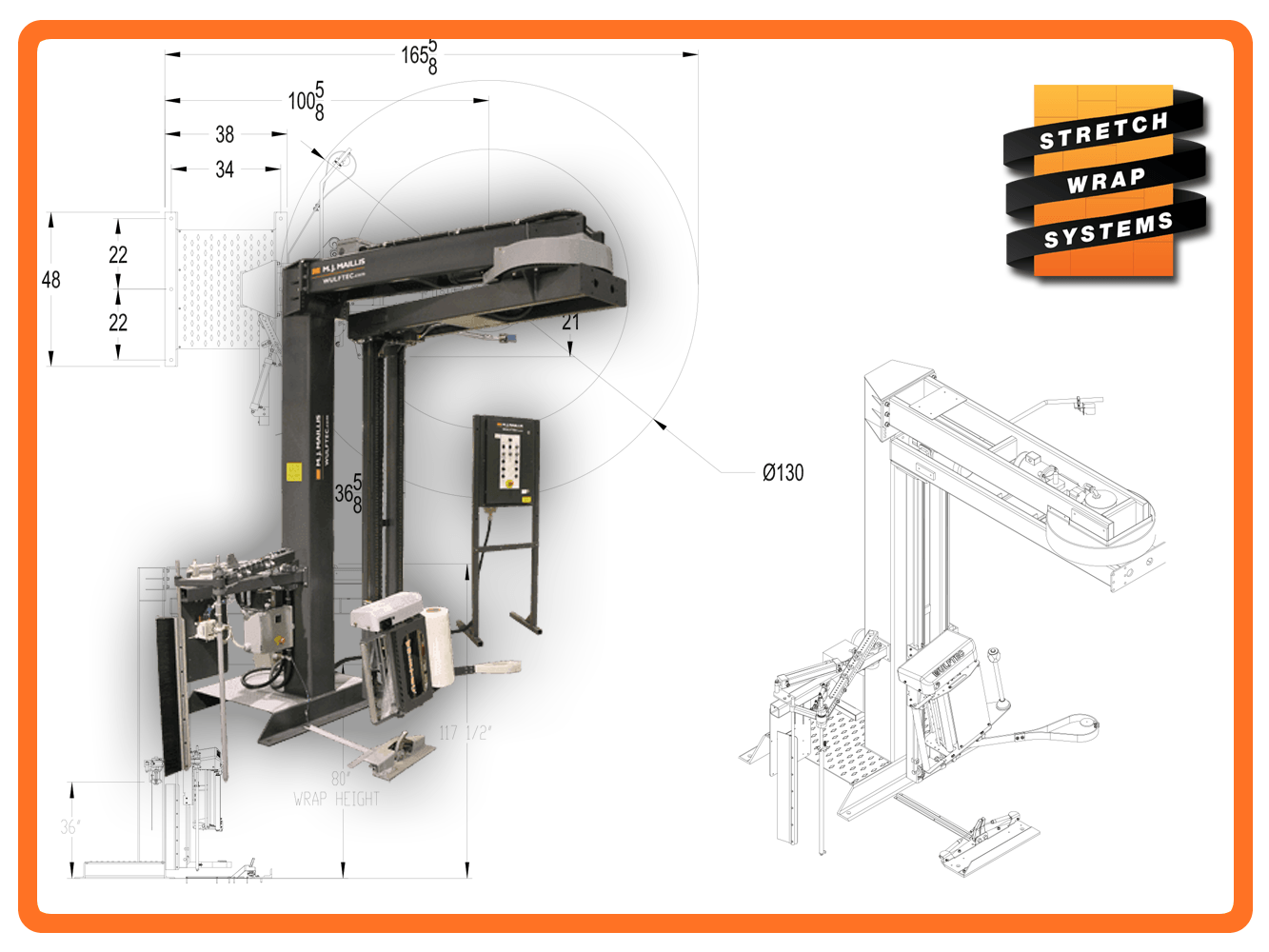

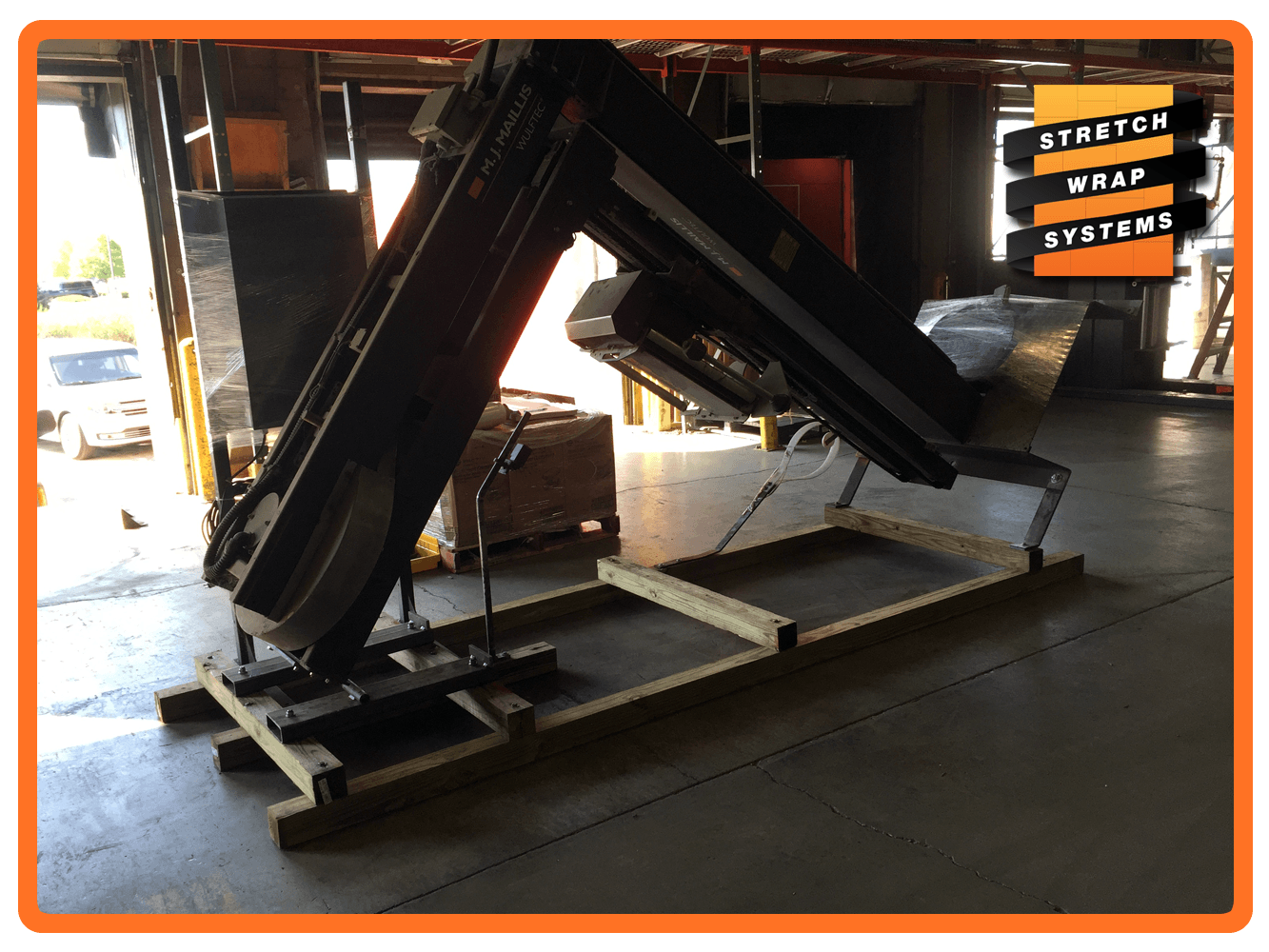

Northwestern PA – 8/16/16

SWS techs Rich and Andrew kicked off Day 1 of this multi day installation of an M.J. Maillis stretch wrapper for a customer in northwestern Pennsylvania. M.J. Maillis stretch wrapper Multi day installation Technicians: Rich & Andrew

Split Base Conversion – 6/2/16

SWS technician Andrew converted this customer’s Highlight Industries Predator High Profile Turntable Stretch Wrapper into a Split Base machine – accommodating a new 48″ – 5000lb scale. Andrew also fitted the machine with a 20″ banding kit – ensuring maximum pallet security Highlight Industries – High Profile Turntable Stretch Wrapper 20″ Carriage 48″ 5000lb Scale… Continue reading Split Base Conversion – 6/2/16

Lancaster, PA – 5/26/16

SWS technician Rich converted this Wulftec SMH-150 Semi-Automatic High Profile Turntable Stretch Wrapper a split base machine to accommodate a scale package Machine: Wulftec SMH-150 Stretch Wrapper Base split by SWS Fitted with scale package Technician: Rich

Camp Hill, PA – 5/16/16

SWS technician Andrew installed and converted this Orion Flex HPA Turntable Automatic Stretch Wrapper into a split base machine to accommodate a scale underneath the turntable. Orion Flex HPA – High Profile Automatic Stretch Wrapping System 20″ carriage Pull cord lanyard Cut machine in half to place scale under the turntable – making a split base… Continue reading Camp Hill, PA – 5/16/16

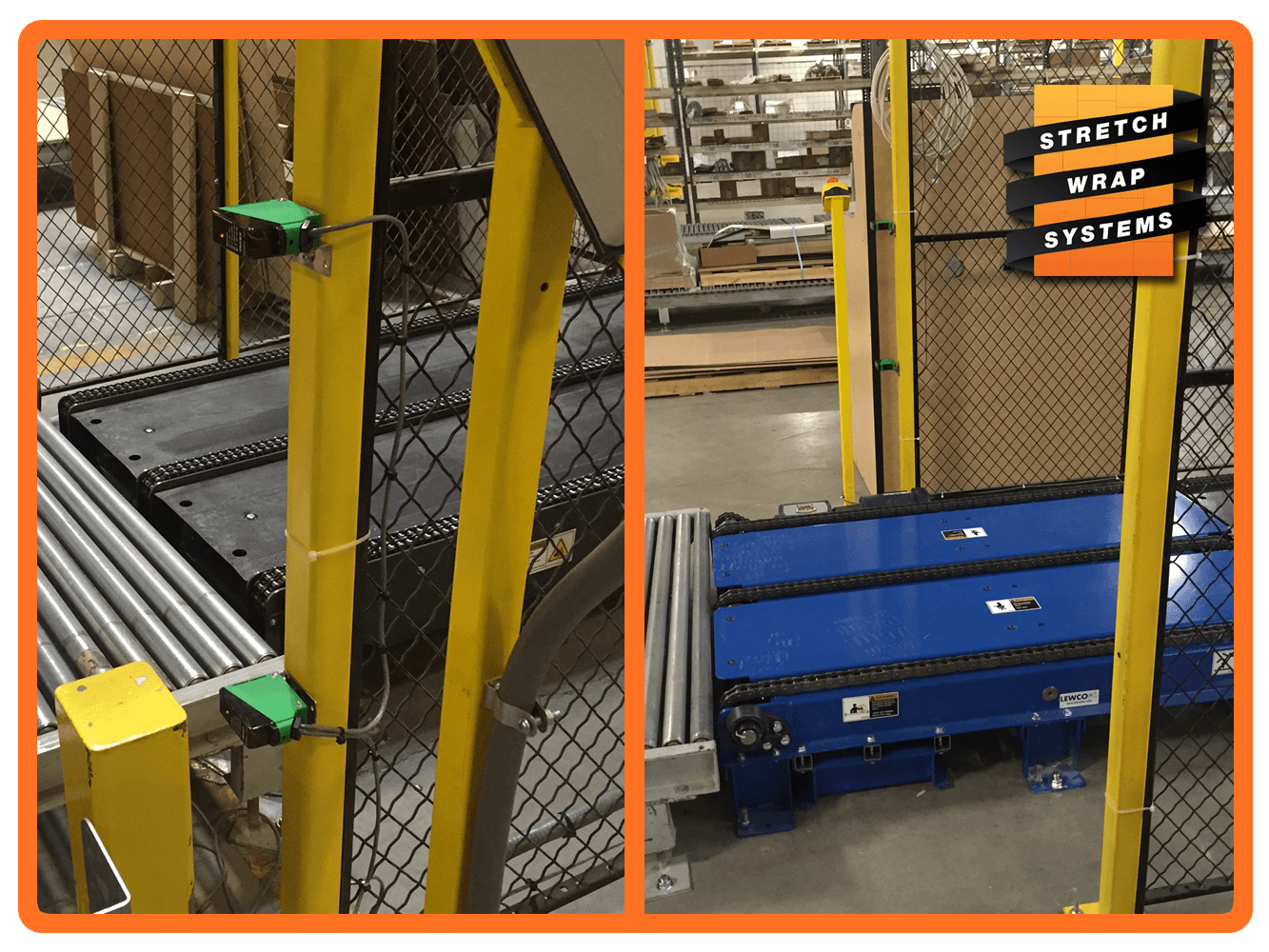

Boston, MA – 5/4/16

SWS technician John added safety Photoeyes and a transfer section of conveyor to a high speed WCRT-200 to protect operators and not lose a staging position on the outfeed side. Photoeyes only muting when loads are entered into the system and when loads are exiting. Added Programming of the CompactLogix PLC and Panelview 600 Plus. … Continue reading Boston, MA – 5/4/16

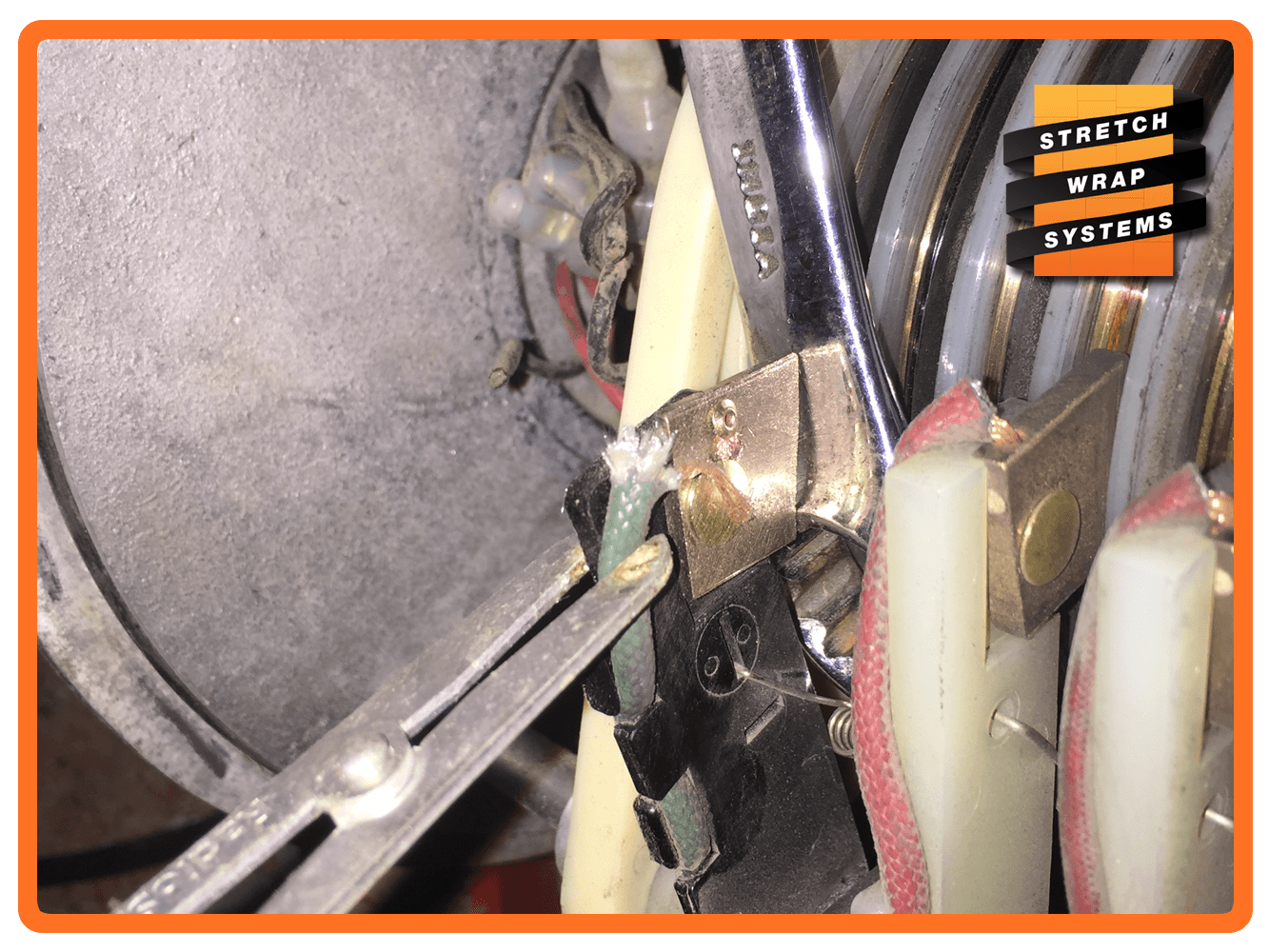

Emergency Service – 4/23/16

This company was looking at being down for 4 weeks after their automatic turntable wrapper suffered a broken slip ring – $3000 and a 4 week wait! John went in Saturday morning at 5 am and with some patience and little bit of soldering, was able to rebuild a severely twisted slip ring and have… Continue reading Emergency Service – 4/23/16

Virginia – 3/23/16

Customer has a Wulftec WCRT with a list of issues. Most importantly, a lot of film breaks and the inability to run one side cling with the slip side out. Total rebuild of film carriage Reprogramming of the film feed system. Lead tech: John “It’s quite obvious you guys know your stuff. This machine hasn’t… Continue reading Virginia – 3/23/16

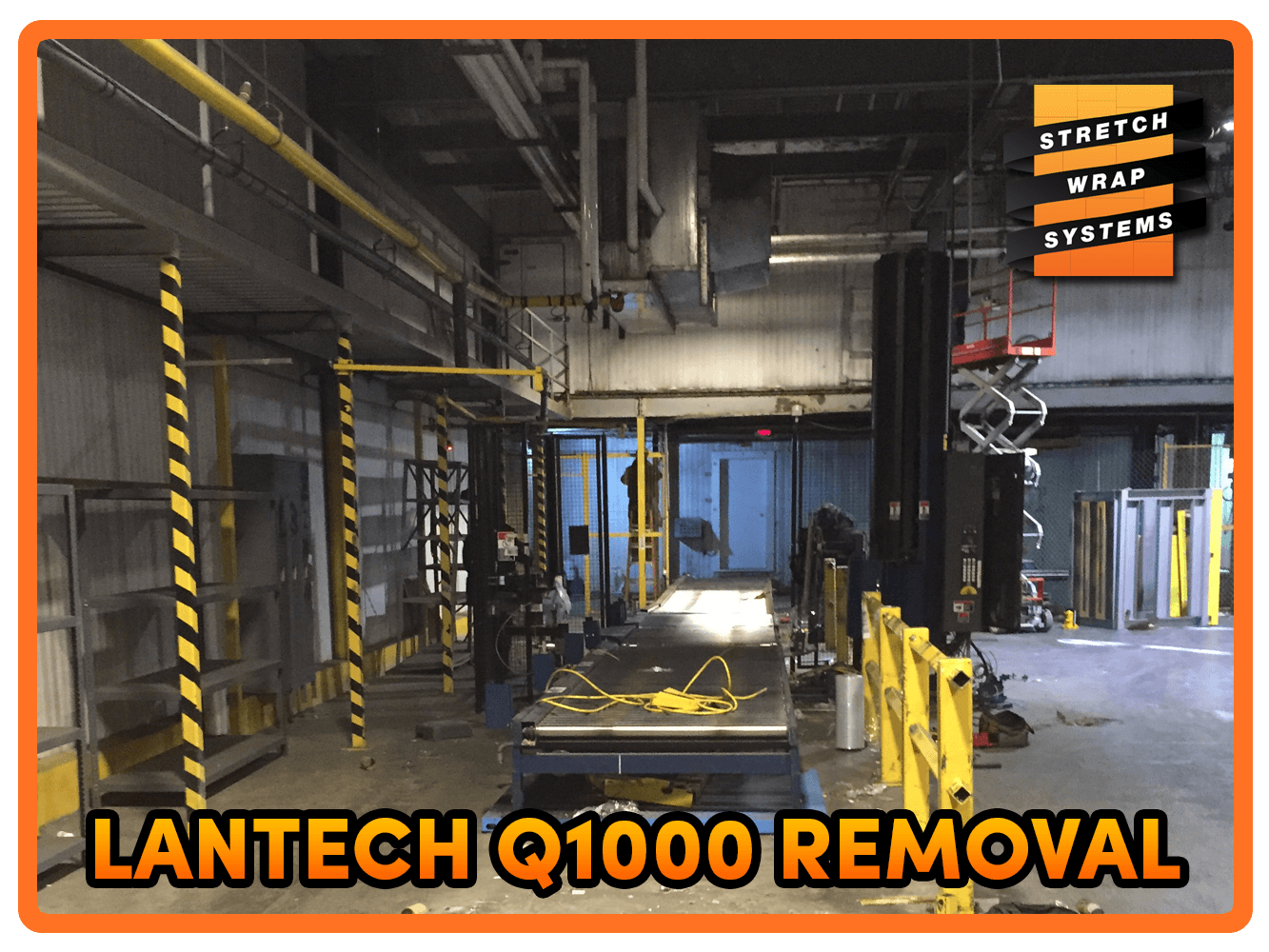

Central NJ – 2/26/16

The Wulftec WCRT-200 Automatic Rotary Arm Stretch Wrapper awaits installation while the Lantech Q1000 is tore down and removed from the freezer/warehouse. Your guys are the real deal…I have seen very few people that could do the work these guys can do and do it in conditions like we have. To say I am impressed… Continue reading Central NJ – 2/26/16

Central NJ – 2/26/15

We’re in central New Jersey this weekend doing a multi day installation. Today we’re removing a Lantech Q1000 to make way for a new Wulftec in a -15° environment! Old Machine: Lantech Q1000 Stretch Wrapper Pending Installation: Wulftec WCRT-200 Stretch Wrapper “Your guys are the real deal…I have seen very few people that could do… Continue reading Central NJ – 2/26/15

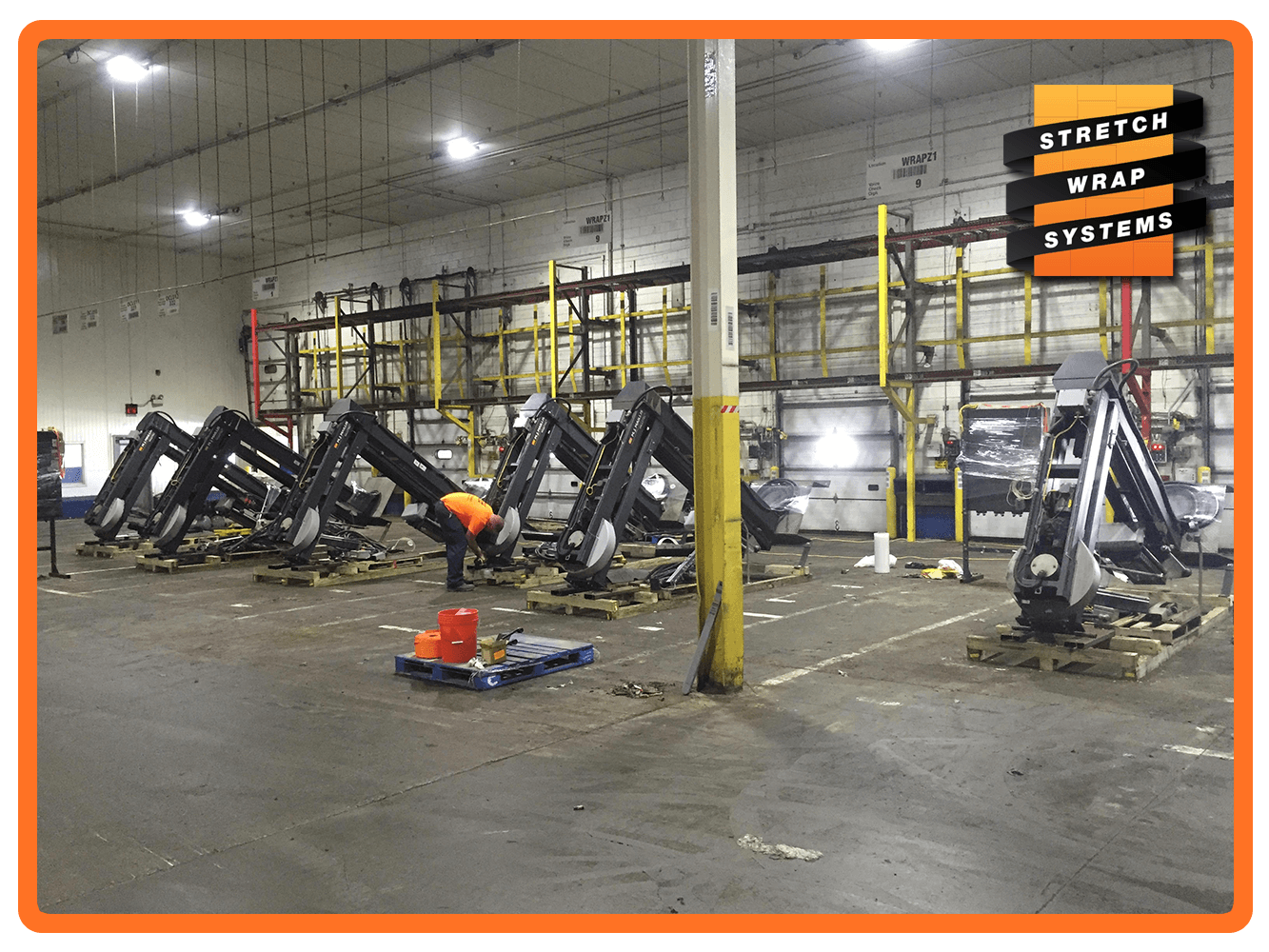

Daytona, FL – 2/28/16

SWS technician Tiger will be in Daytona, FL at a customer’s new warehouse for their GO-LIVE event, overseeing the start up of their new wrappers, which we installed in October 2015. Wulftec WRTA-150 Sunday 2/28/16 thru Wednesday 3/2/16 5 machines Units installed in October 2015 Technician: Tiger

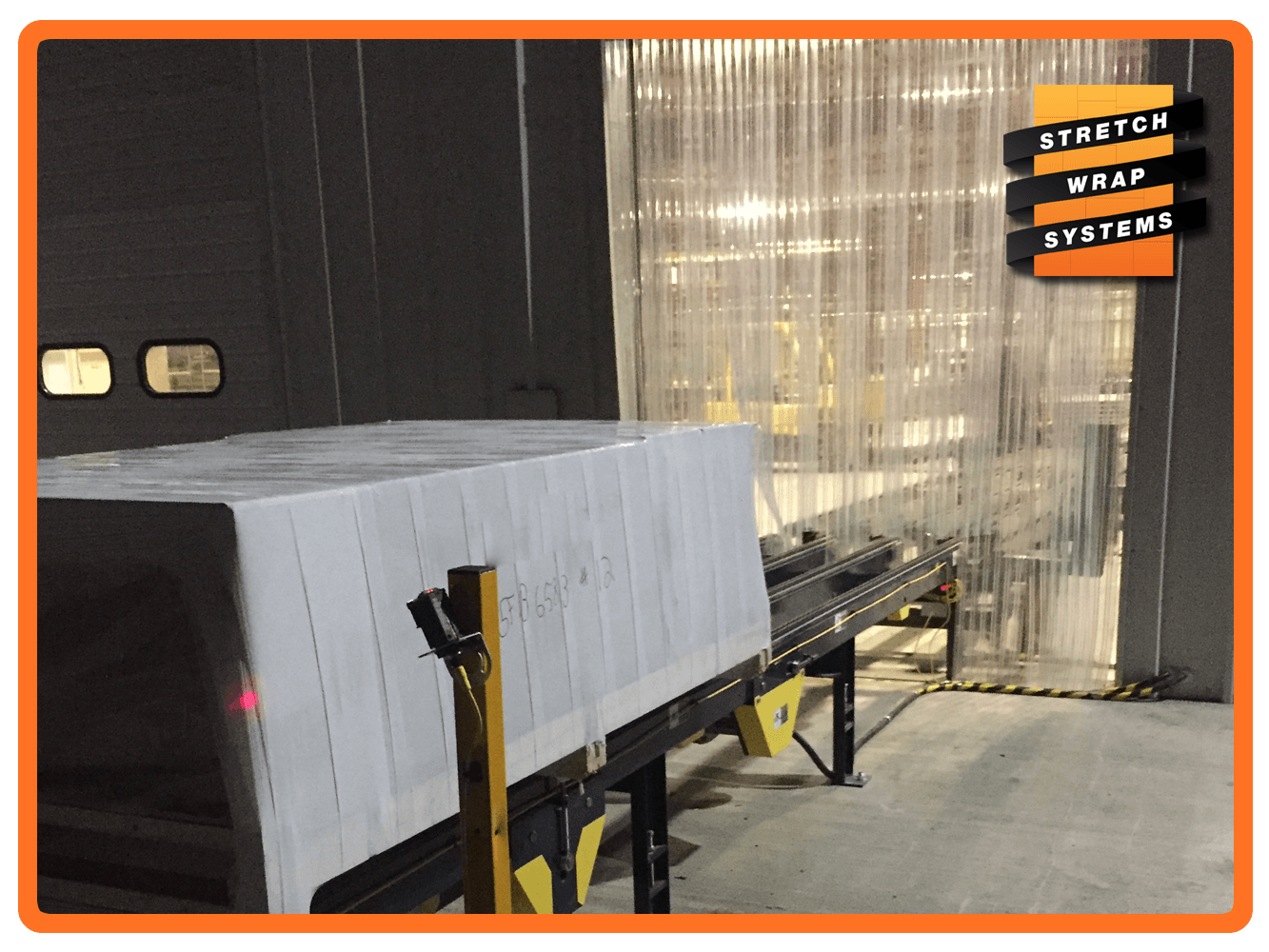

New York Metro. – 12/17/15

The customer wanted pallets to go out through a wall that has a garage door in it Added a section of conveyor outside/all wash down components. PLC Controls Conveyor & Door Technician: John

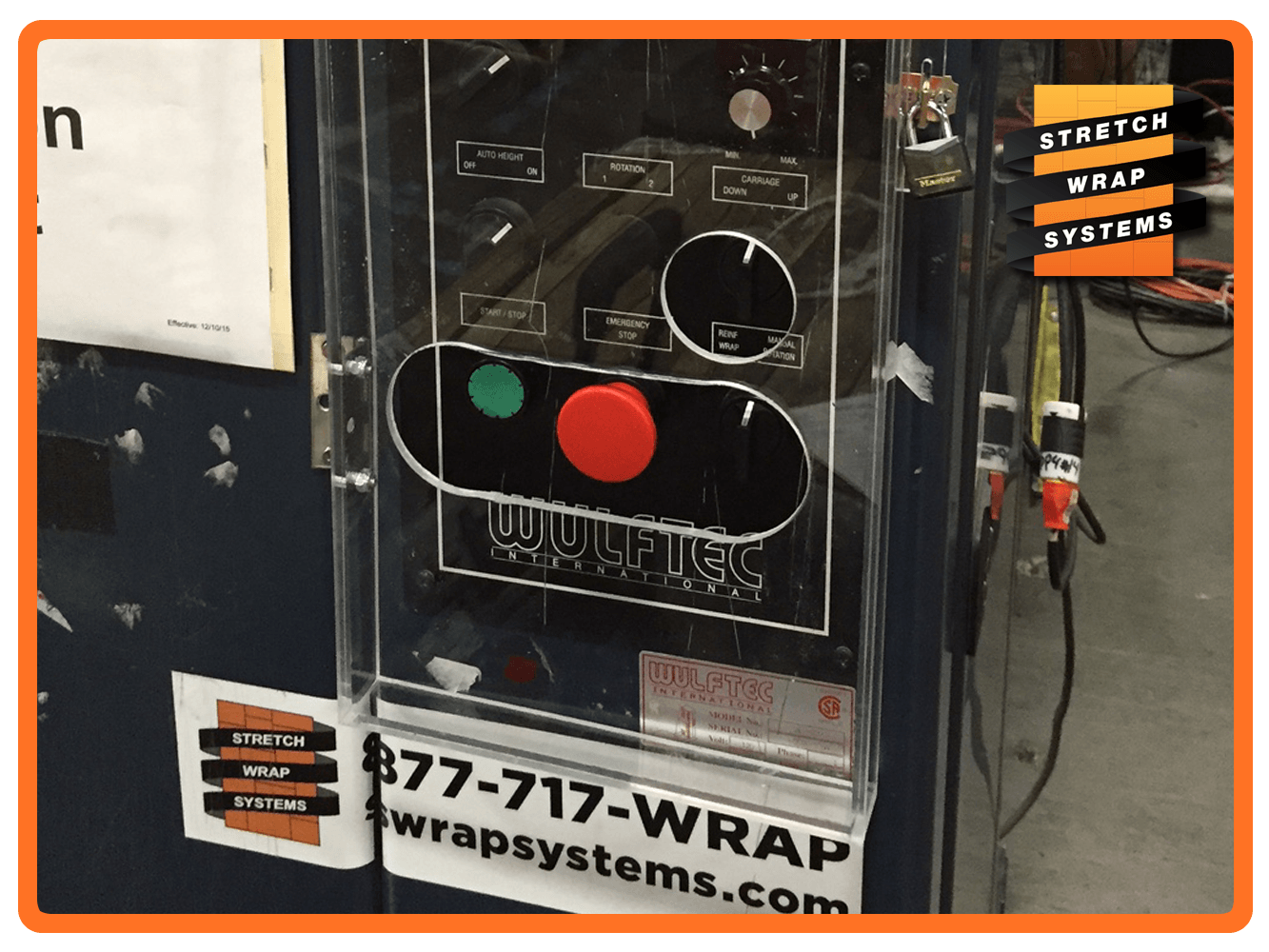

Central PA – 12/11/15

SWS technician Andrew was in central Pennsylania last Friday retrofitting 4 or a customer’s machines with control panel covers to prevent operators from changing the controls. Estimated film savings – reduction by 35% Lead Technician: Andrew

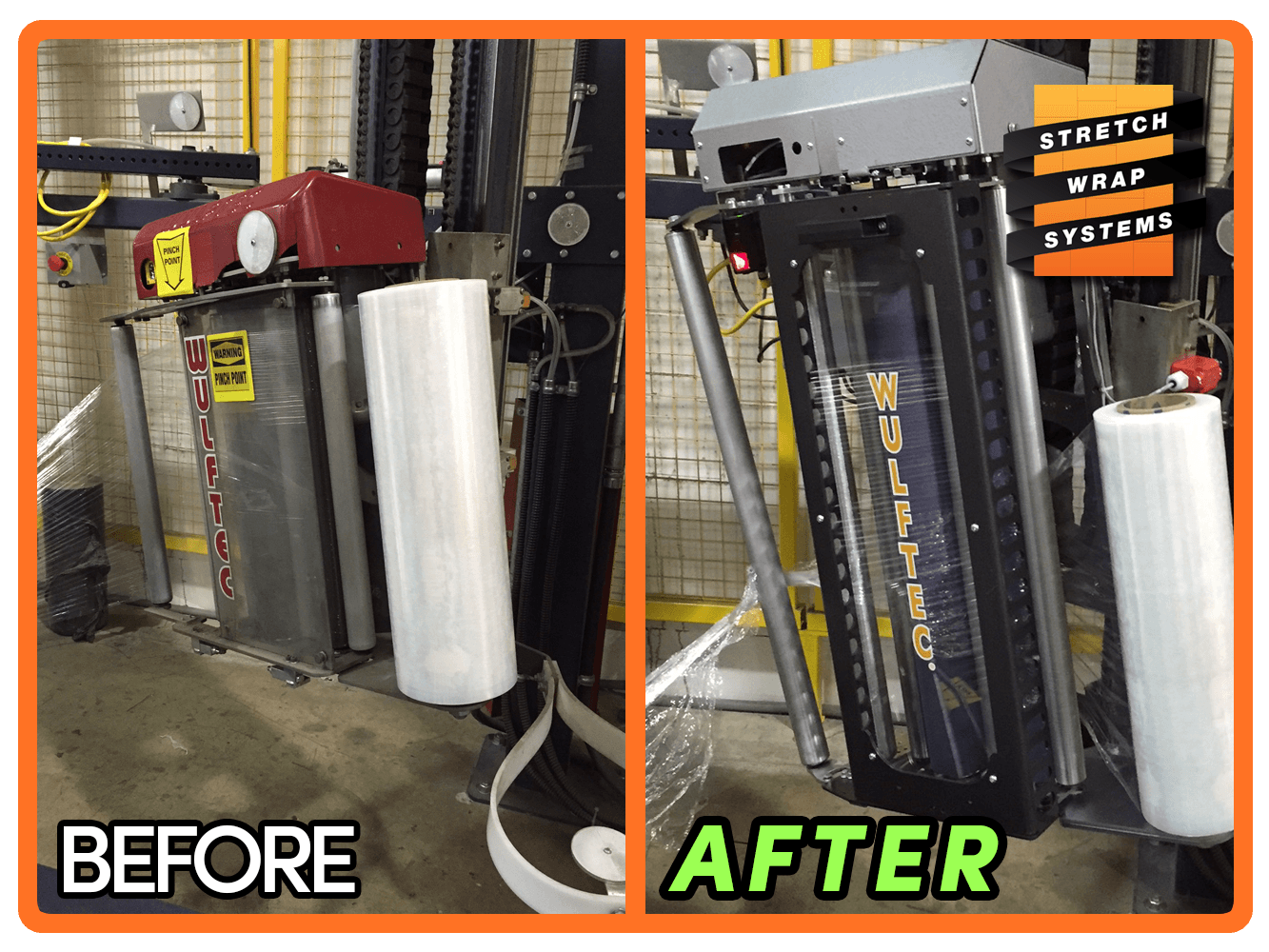

Central PA – 11/16/15

SWS retrofitted a customers Orion machine with a 30″ Wulftec carriage. Reducing the number of revolutions from 16 to a mere 5! Saving the customer money by cutting labor hours and material costs Goal: reduce film usage and increase cycle times Wulftec carriage onto a Orion wrapper Lead tech: John

Central PA – 11/12/15

Customer had a carriage that was not ideal for their application. With some added components, SWS technician John, changed the direction that the film flows through the carriage. This helped to achieve the correct and desired pre-stretch. 30″ carriage repair Lead tech: John Customer reduced film usage by approximately 50%

Central PA – 10/29/15

SWS tech Andrew was in central PA upgrading this Wulftec machine to a 30″ carriage from a 20″. Upgrading to a 30″ carriage reduced the number of pallet revolutions from 19 with 20″ film to a mere 7 revolutions with 30″ film. Payback/ROI – 6 months Lead tech: Andrew 30″ carriages result in less wear… Continue reading Central PA – 10/29/15

Pittsburgh, PA – 9/19/15

SWS techs, John and Andrew, were in Pittsburgh on Saturday assisting in a warehouse relocation Disassembled 6 machines Cleaned and repainted PM all units Lead techs: Andrew and John

York, PA – 9/19/15

SWS recently moved a machine for a client who was relocating Lead Tech: Tiger