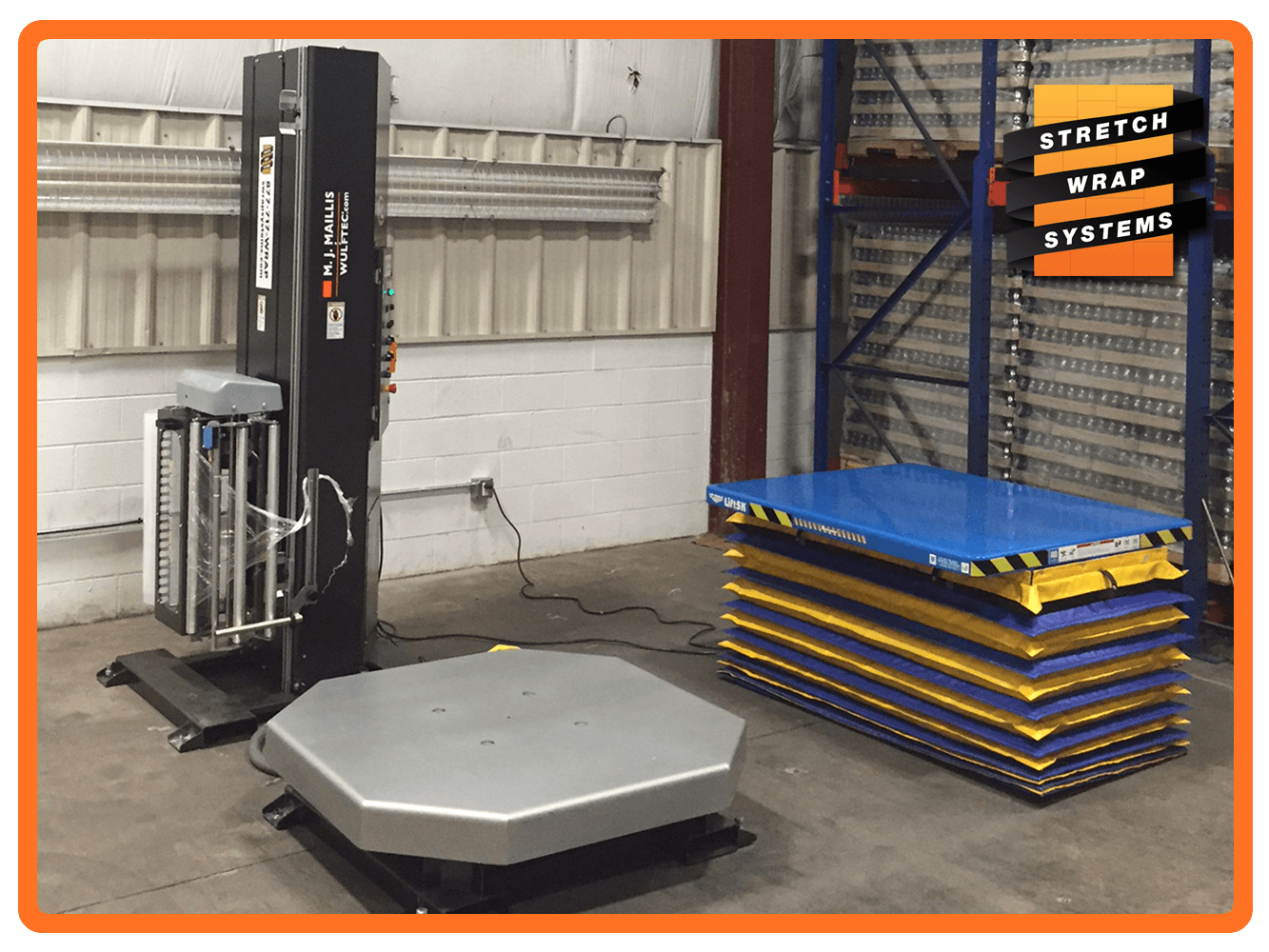

SMH-HVY Split Base Turntable Stretch Wrapper & Top Sheet Dispenser Industrial Supply Company Split base machine High profile turntable 8000lb load capacity Pull cord starter Technician: Kyle

Portfolio Categories: Split Base

Central, PA – 5/4/18

SMH-SPL Semi-Automatic Turntable Wrapper Window manufacturer 30″ carriage Password protected panel view screen Wrap pattern selector Banding film/device for super strength Oversized turntable 10,000 LB scale Wrapping loads from 40″ x 48″ to up to 11 ft long Technicians: Andrew & Tiger “I would like to let you know that I am very impressed with… Continue reading Central, PA – 5/4/18

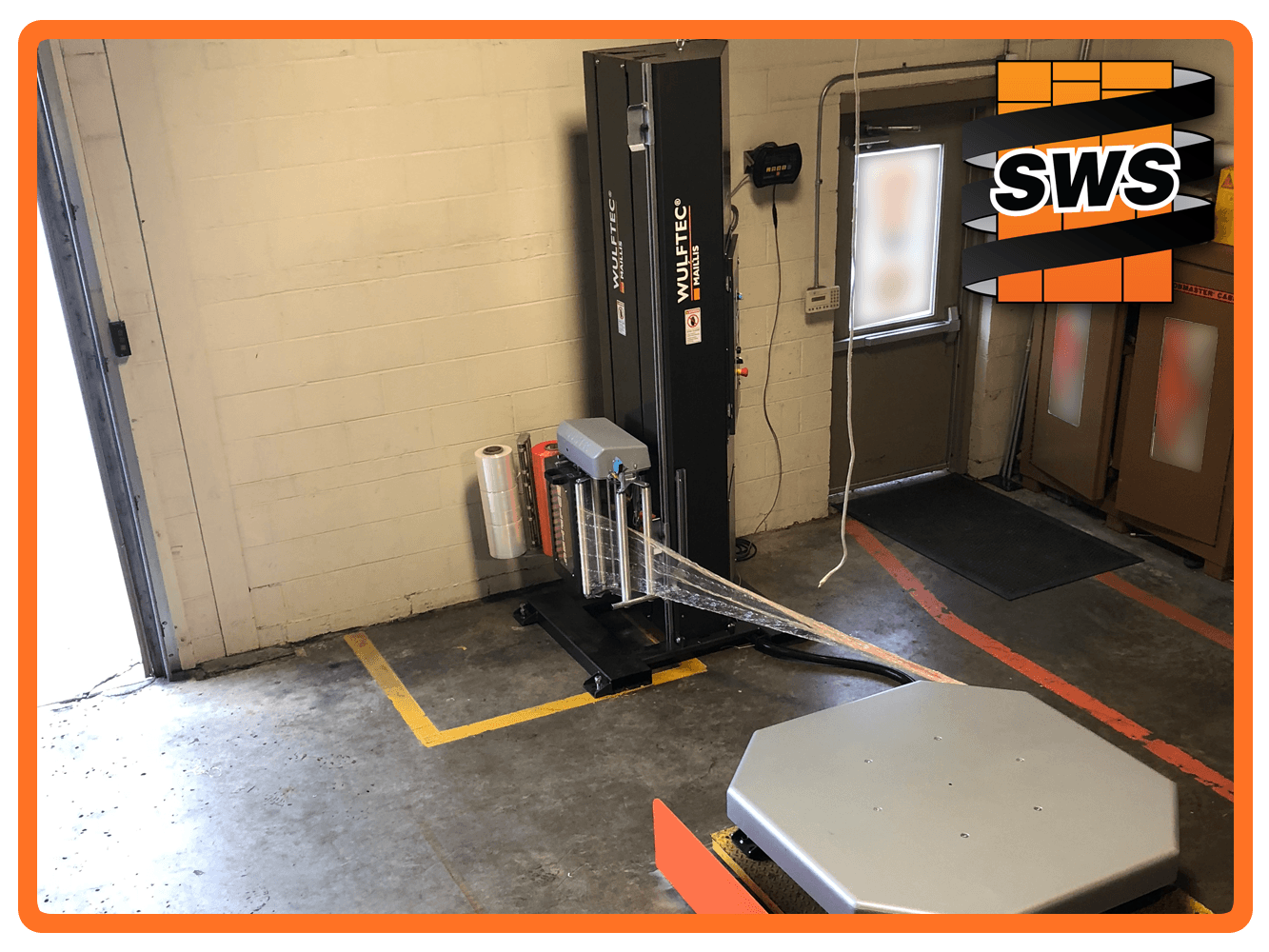

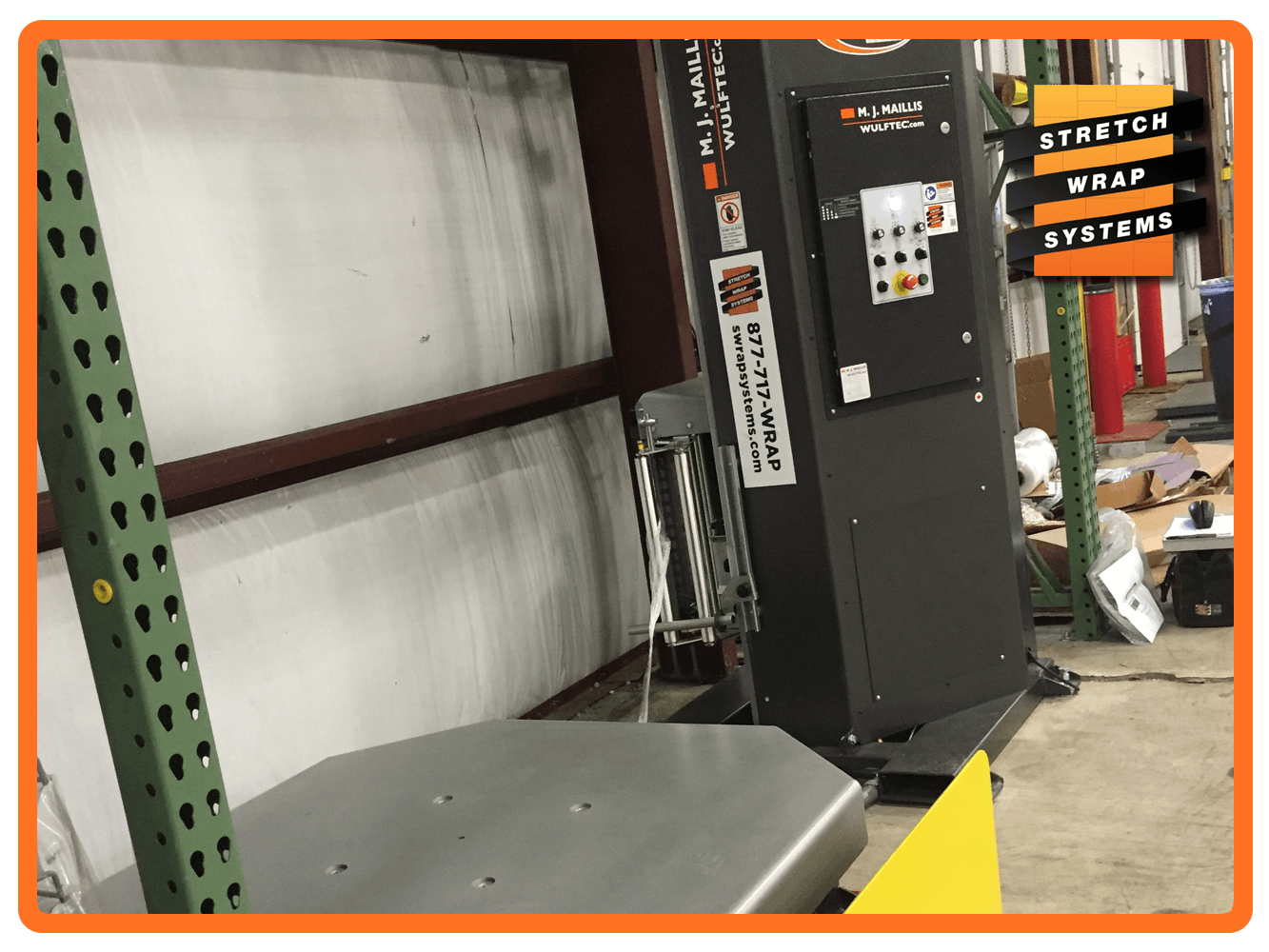

Eastern PA – 8/1/17

Wulftec SMH-150 Semi-Automatic Turntable Stretch Wrapper 20″ carriage Banding device Split base to accommodate up to 12′ pallets Technician: Tiger

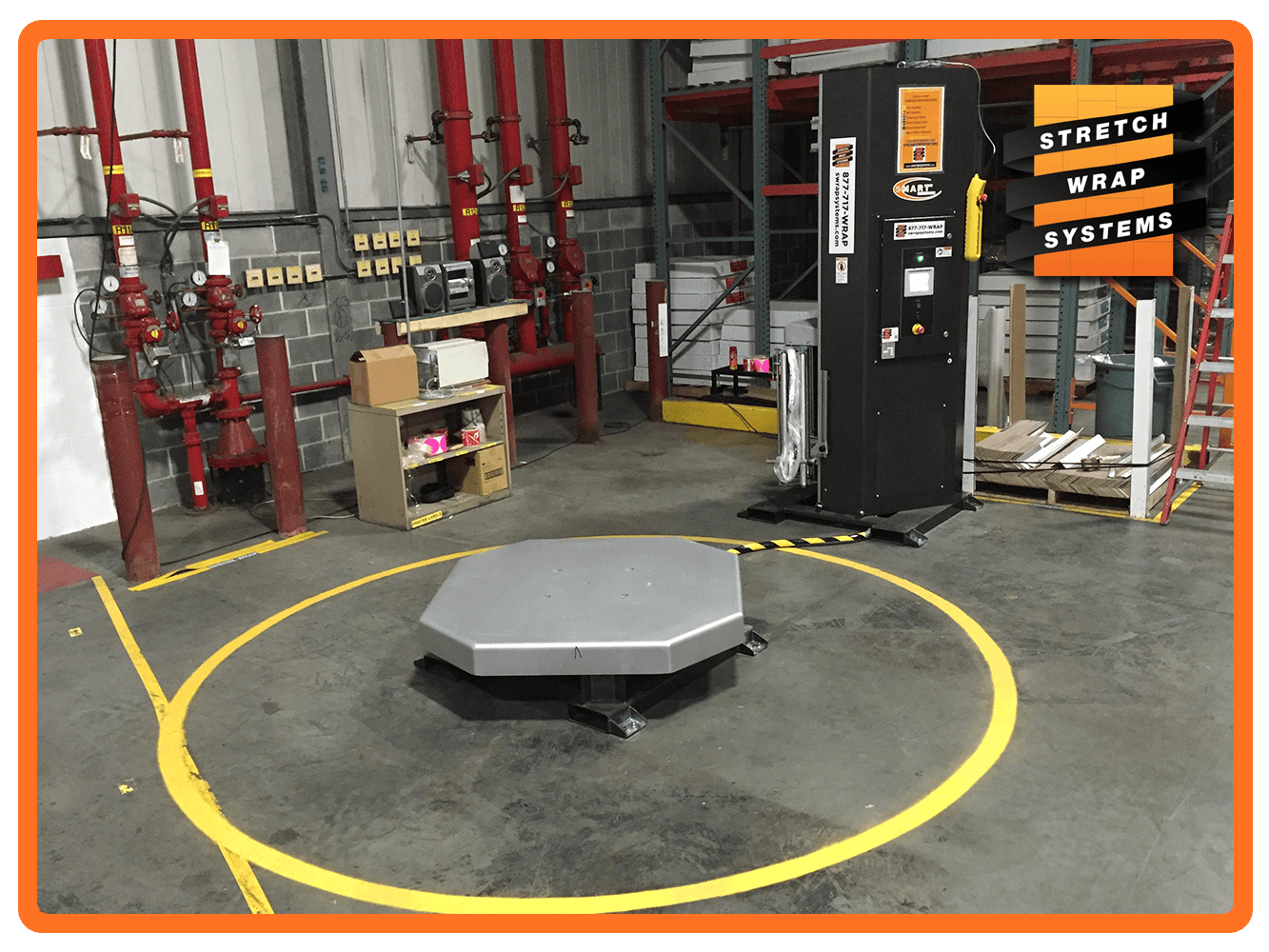

Central PA – 12/12/16

Wulftec SMH-SPL Semi-Automatic Turntable Stretch Wrapper SWS technician Tiger installed this new SMH-SPL turntable stretch wrapper with a 30″ stretch film carriage. This small footprint split base stretch wrapper is outfitted with a floor mounted scale and digital readout. 30″ film carriage Floor mounted scale Digital scale readout Small footprint split base design Technician: Tiger

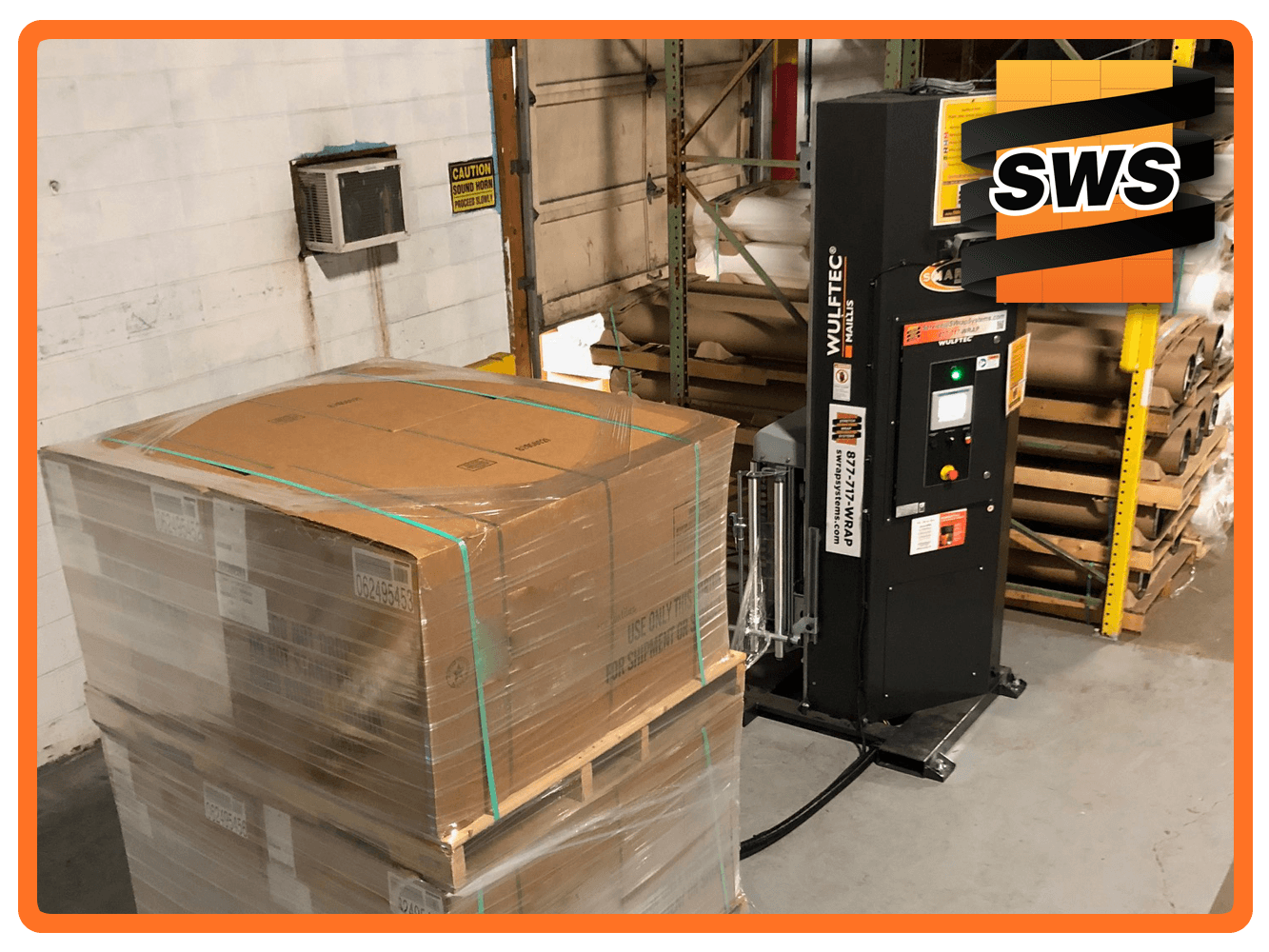

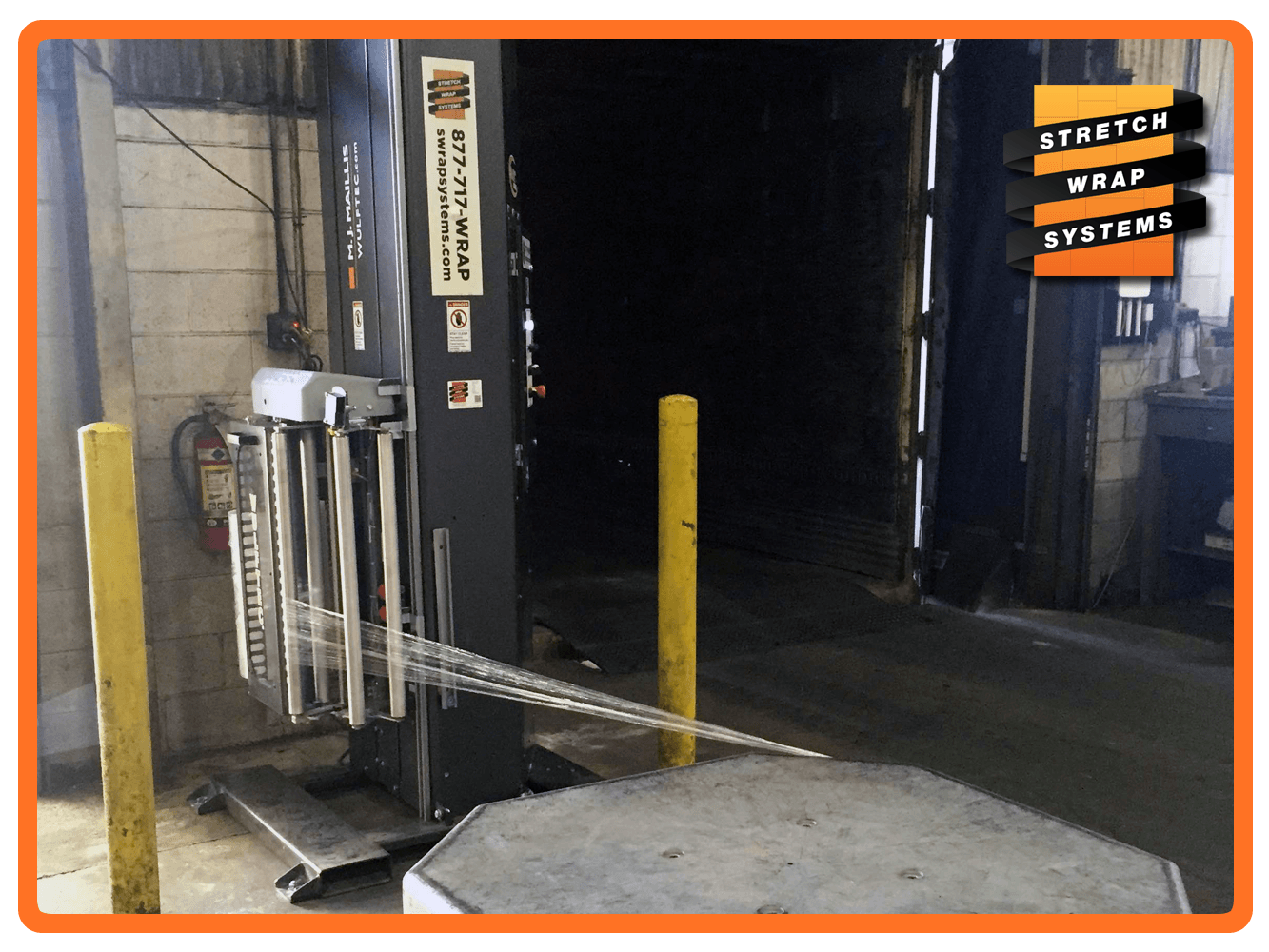

Hazelton, PA – 10/21/16

SWS technicians Andrew and Matt converted this WHP Stretch Wrapper into a Split Base Turntable Stretch Wrapper and integrated a scale for the customer before installing it. WHP to split base conversion Technicians: Andrew & Matt

Central PA – 7/22/16

Andrew installed this Wulftec SMH-SPL Turntable Stretch Wrapper with a 30″ carriage and an additional scale package for a company in central Pennsylvania. The top mounted scale display shows the weight of the current pallet on the turntable. The SMH-SPL has a 5000lb pallet weight capacity. Basic control panel 30″ carriage Scale package Technician: Andrew

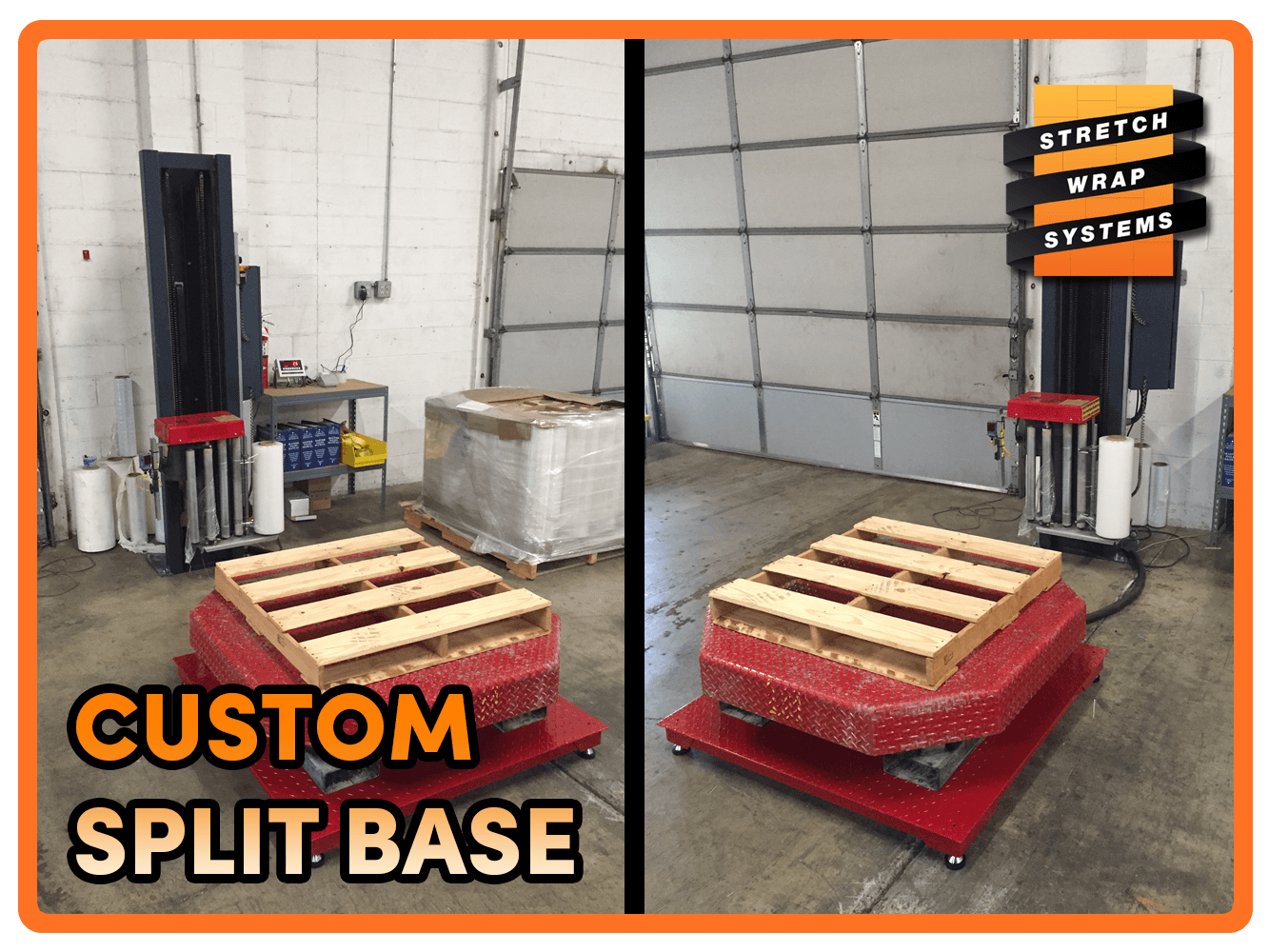

Split Base Conversion – 6/2/16

SWS technician Andrew converted this customer’s Highlight Industries Predator High Profile Turntable Stretch Wrapper into a Split Base machine – accommodating a new 48″ – 5000lb scale. Andrew also fitted the machine with a 20″ banding kit – ensuring maximum pallet security Highlight Industries – High Profile Turntable Stretch Wrapper 20″ Carriage 48″ 5000lb Scale… Continue reading Split Base Conversion – 6/2/16

Lancaster, PA – 5/26/16

SWS technician Rich converted this Wulftec SMH-150 Semi-Automatic High Profile Turntable Stretch Wrapper a split base machine to accommodate a scale package Machine: Wulftec SMH-150 Stretch Wrapper Base split by SWS Fitted with scale package Technician: Rich

York, PA – 2/09/16

SWS technician Andrew installed and customized this used split base machine, removing the base and adding a scale. WHP-150 20″ carriage 48 x 48 scale with printer Custom split base Technician: Andrew

Western, PA – 1/6/16

SWS technicians Andrew & John were in western Pennsylvania installing a Wulftec SMH-SPL Split Base Semi-Automatic Stretch Wrapper 30″ carriage Standard Panel 90 degree table indexing foot pedal Hydraulic pallet lift Technicians: Andrew, John

Pittsburgh Metro. – 12/10/2015

20″ Film, Wulftec Split Base Machine with an integrated Scale and top mounted indicator. Installer: John Koehler

Central, PA – 10/14/15

SWS installs SMH-SPL Semi-Automatic Turntable Stretch Wrapper Wraps pallets from 48″ to 120″ 30″ carriage Panel view Lanyard selector Custom SWS programming Lead Tech: Andrew Reduces daily labor time by approximately 6 hours! Reduced wrapping from approximately 3 minutes to 1!

Western PA – 8/15/15

SWS installed this customers second unit in western Pennsylvania. Over sized 72″ turntable Wrap pattern selector Panel view screen with custom patterns Rapid Film 30″ carriage Customer wrapping corrugated products Lead tech: Tiger

Punxsutawney, PA – 7/28/15

SWS installs SMH-SPL 150 Semi-Automatic Stretch Wrapper in Punxsutawney 30″ carriage Rapid Film Scale package Lead tech: Rich / Andrew

Allentown, PA – 6/2/15

SMH-SPL Machine 30″ Carriage Machine bought for oversized loads unable to be wrapped by other machines Lead tech: John

Western PA – 12/22/14

Dual turn table stretch wrapper with scales 30″ Carriage Top Sheet Switch for manual top sheet placement during wrap cycle Guards to protect turntables Pull Cord Start Rapid Film Dusty environment, wrapping totes and bag Lead tech: John