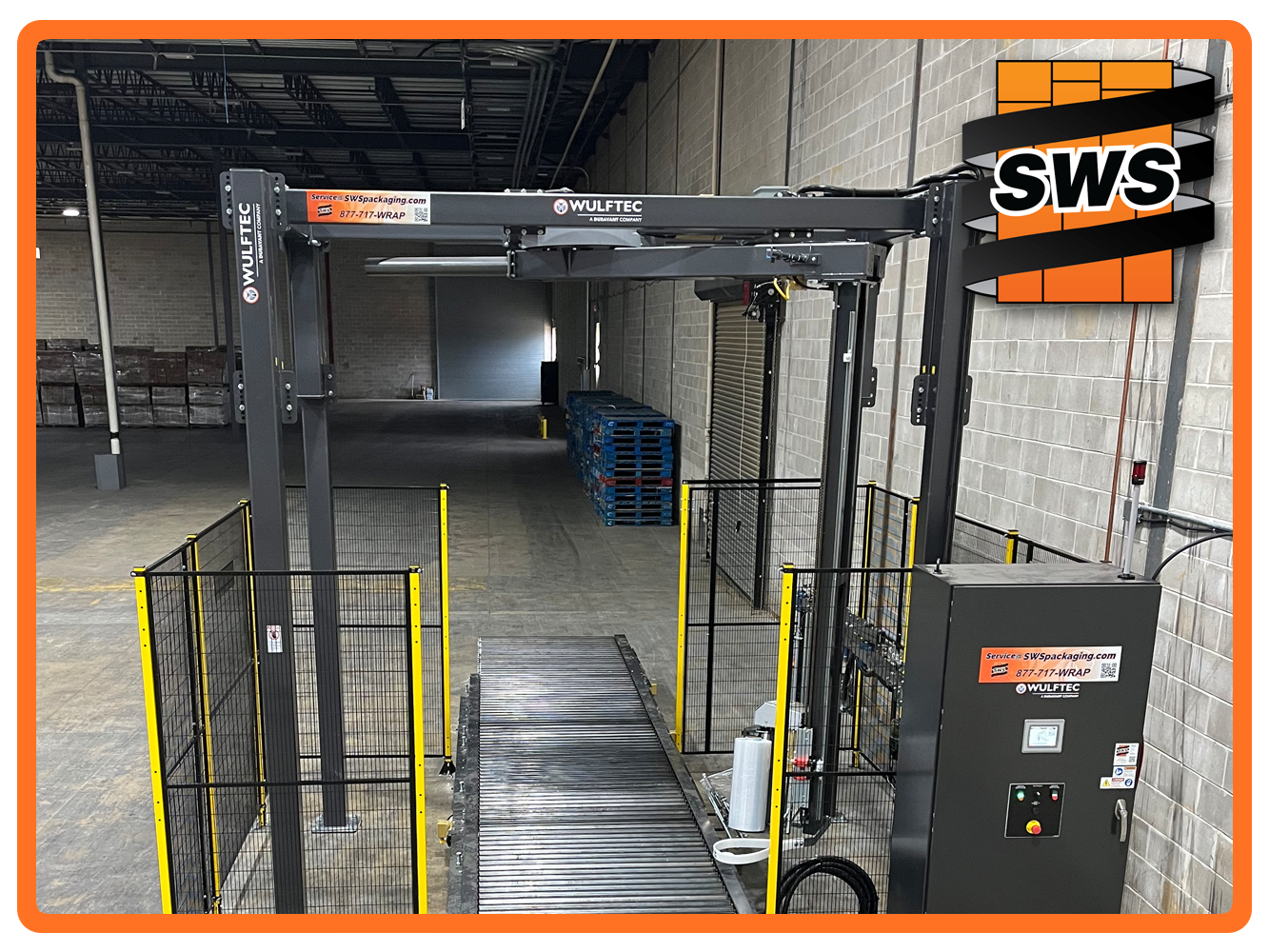

This Wulftec WCRT-200 is a high powered automatic wrapping solution that allows for the queing of loads on the infeed and outfeed conveyors. Additionally, this unit includes a inline topsheet applicator and heat sealer.

Portfolio Categories: WCRT-200

Wharton, NJ – 3/20/24

South Brunswick, NJ – 3/12/24

This is this customers third WCRT-200 that we’ve installed in just a few weeks. They’ve opted for these powerful workhorse machines to replace the antiquated stretch wrappers that they had previously been using.

South Brunswick, NJ – 3/7/24

This is the second of three WCRT-200 conveyorized stretch wrappers that this customer has bought. The WCRT-200 is a robust wrapping solution an infeed and outfeed conveyor that allow for the queuing of pallets to be wrapped and conversely picked up on the other side. A truly fully automatic and hands free approach to wrapping.

South Brunswick, NJ – 2/22/24

The WCRT-200’s performance speaks for itself and it didn’t take much convincing for this customer to choose the ultra high throughput wrapping solution from Wulftec for their facility. With a capacity of around 100 loads per hour, this system is designed for speed and flexibility as it can quickly wrap pallets while also allowing for… Continue reading South Brunswick, NJ – 2/22/24

New Holland, PA – 2/16/24

This customer needed an efficient machine for wrapping industrial materials in a fast paced production environment – something like the WCRT-200 with an infeed and outfeed conveyor that allows the queing of multiple pallets. Capable of wrapping up to and in some cases over 100 loads per hour, the WCRT-200 is a dependable workhorse for… Continue reading New Holland, PA – 2/16/24

Eastern PA – 10/27/23

The customer’s new acquisition of the Wulftec WCRT-200 conveyorized rotary arm stretch wrapper marks a notable advancement in their packaging capabilities. With a formidable speed of 17 RPM, the WCRT-200 stands out for its rapid wrapping cycles, enabling the customer to handle greater volumes with increased efficiency. The inclusion of a 30” carriage accommodates a… Continue reading Eastern PA – 10/27/23

Lebanon, TN – 9/20/23

An outdoor products distributor, facing a significant increase in demand for their diverse product range, recognized the necessity to enhance their throughput and efficiency in their packaging and distribution process. To meet this challenge, they invested in the WCRT-200 conveyorized rotary arm stretch wrapper from Wulftec. This state-of-the-art machinery, renowned for its durability and efficiency,… Continue reading Lebanon, TN – 9/20/23

Tinton Falls, NJ – 4/21/23

Caleb and Luke installed this WCRT-200 conveyorized stretch wrapper in New Jersey. With an inline topsheet applicator and an integrated scale on the outfeed conveyor, this customer is able to rapidly wrap their product in the most secure manner possible and get an accurate weight of the wrapped pallet before shipment.

Wharton, NJ – 11/8/22

SWS removed this customer’s old conveyor and wrapper and installed all new conveyor and cabinets with 40 Allen Bradley VFD drives, remote HMIs and large control panels as well as a new dual carriage Wulftec WCRT-200 with 30″ film carriages. A unique aspect of this project was the connection of two parallel conveyor via a… Continue reading Wharton, NJ – 11/8/22

Leola, PA – 10/20/22

The WCRT-200 is a conveyorized rotary arm stretch wrapper with a high output ideal for companies that is an ideal for solution for companies that use forklifts and need a workhorse. This particular model includes an inline load centering device in the wrap zone.

San Bernardino, CA – 7/1/21

WCRT-200 Light curtain safety lightcurtain safety package

Waterville, ME – 5/18/21

WCRT-200 Rotary Arm Wrapper

Lancaster, PA – 9/23/21

WCRT-200 Scale Outfeed scale top sheeter top sheet applicator quick stop fence gate

Lebanon, PA – 11/17/21

This customer purchased not one but two WCRT-200 conveyorized rotary arm stretch wrappers, adding significant throughput to their packaging line. These machines were installed and integrated with this customer’s existing safety cell and packaging line.

St. Albans, VT – 4/15/21

The WCRT-200 is a high throughput conveyorized wrapping solution that can support an in-cycle top sheet applicator and a number of other options. This unit features a safety fencing package complete with a quick stop fence gate.

Fairless Hills, NJ – 2/11/21

This wrapper is a beast of a machine running at 17 RPM with chain driven conveyor and in cycle top sheet applicator. This is a truly automatic wrapping solution – drop off a pallet and pick it up on the other end of the conveyor. This unit includes a category 4 safety package with complete… Continue reading Fairless Hills, NJ – 2/11/21

Lancaster, PA – 10/21/20

Two WCRT-200 Conveyorized Rotary Arm Stretch Wrappers 30 RPM HIGH/LOW Voltage cabinet split All motor disconnects All VFDs on ethernet for diagnostics without opening the cabinet 1 machine with top platen and top platen flap holders Technician: John Koehler

Allentown, PA – 9/11/20

Two Wulftec WCRT-200 Conveyorized Rotary Arm Stretch Wrappers WRAPPER 1 —————— 30 RPM 30″ carriage Integrated load popup Light curtains on infeed and outfeed 3 sections of conveyor Data tracking Ethernet comms to palletizer upstream and conveyor system downstream WRAPPER 2 —————— 30 RPM 30″ carriage Integrated load popup Top platen with tab folder Light… Continue reading Allentown, PA – 9/11/20

Cleveland, OH – 01/06/20

WCRT-200 Dual Carriage Automatic Rotary Arm Wrapper Dual high speed carriages Load pop up mechanism Technicians: Chuck, Chet