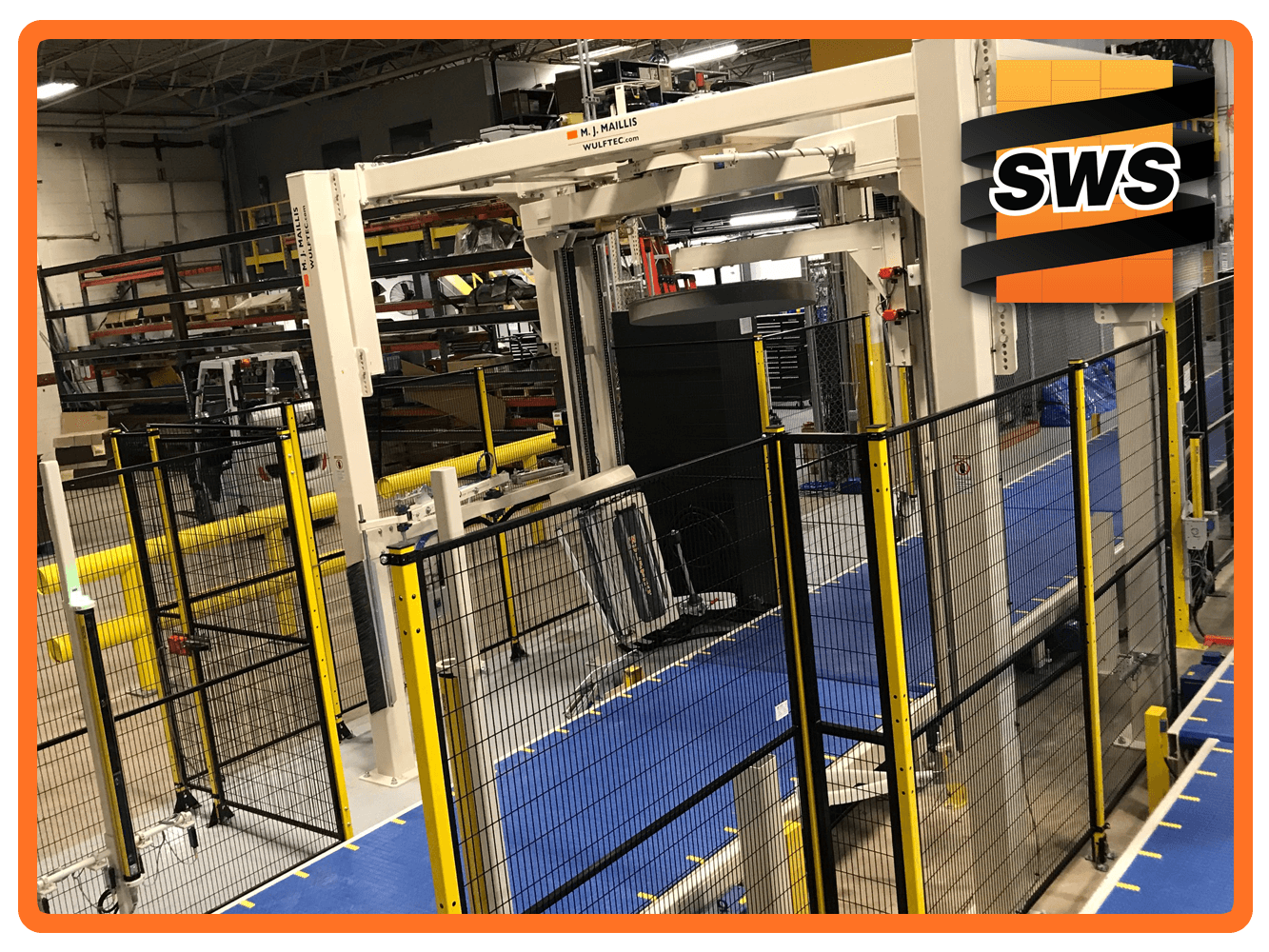

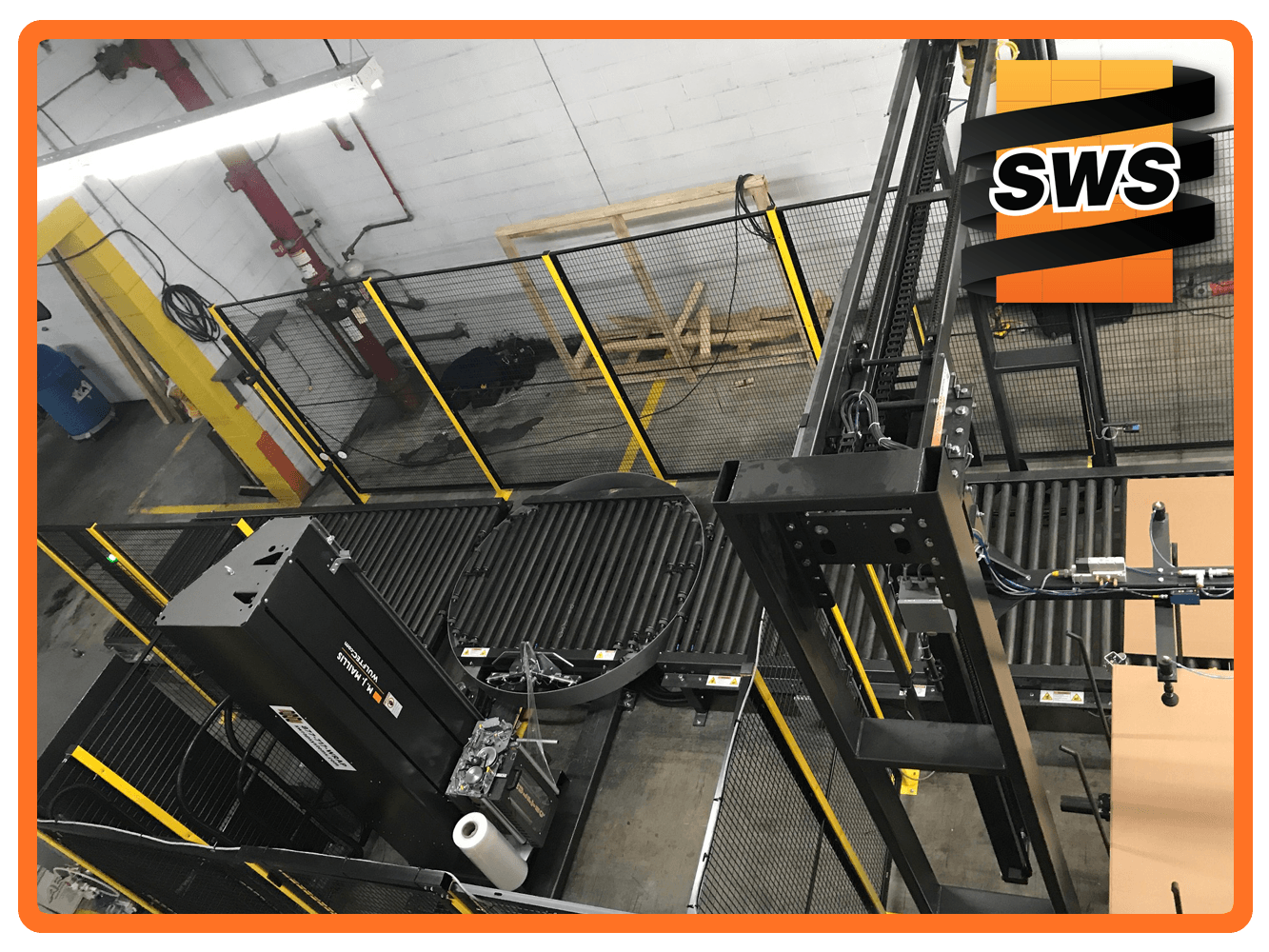

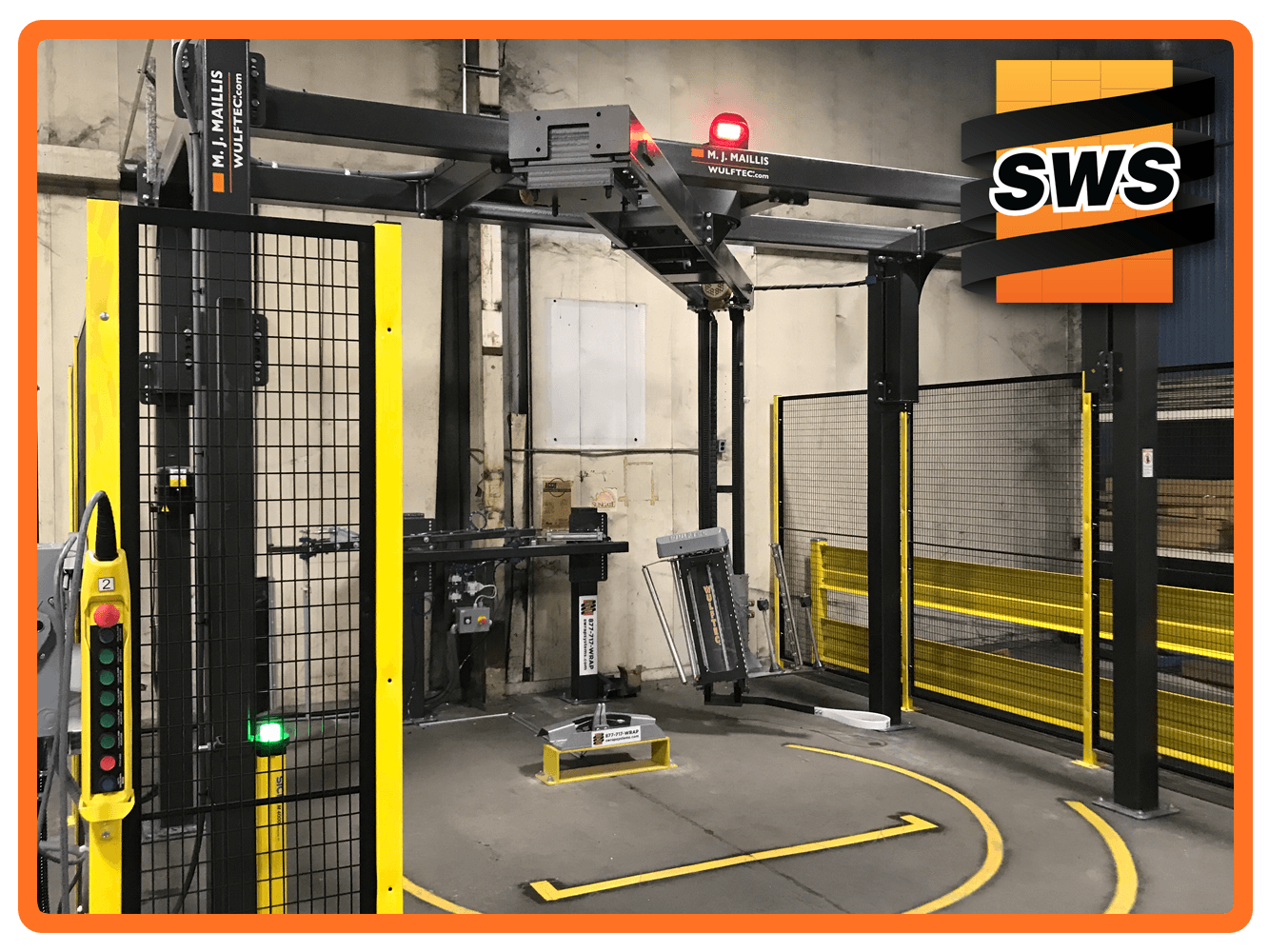

WCRT-200 Conveyorized Automatic Rotary Arm Wrapper Corrugated manufacturer 35 RPM Rotary Arm WCRT-200 over existing conveyor. 30” Film Carriage Top Platen to hold loads Together while wrapping. Remote Pedestal Station for Operators. Technicians: John K & Kyle K

Portfolio Categories: automatics

Boston, MA – 4/9/18

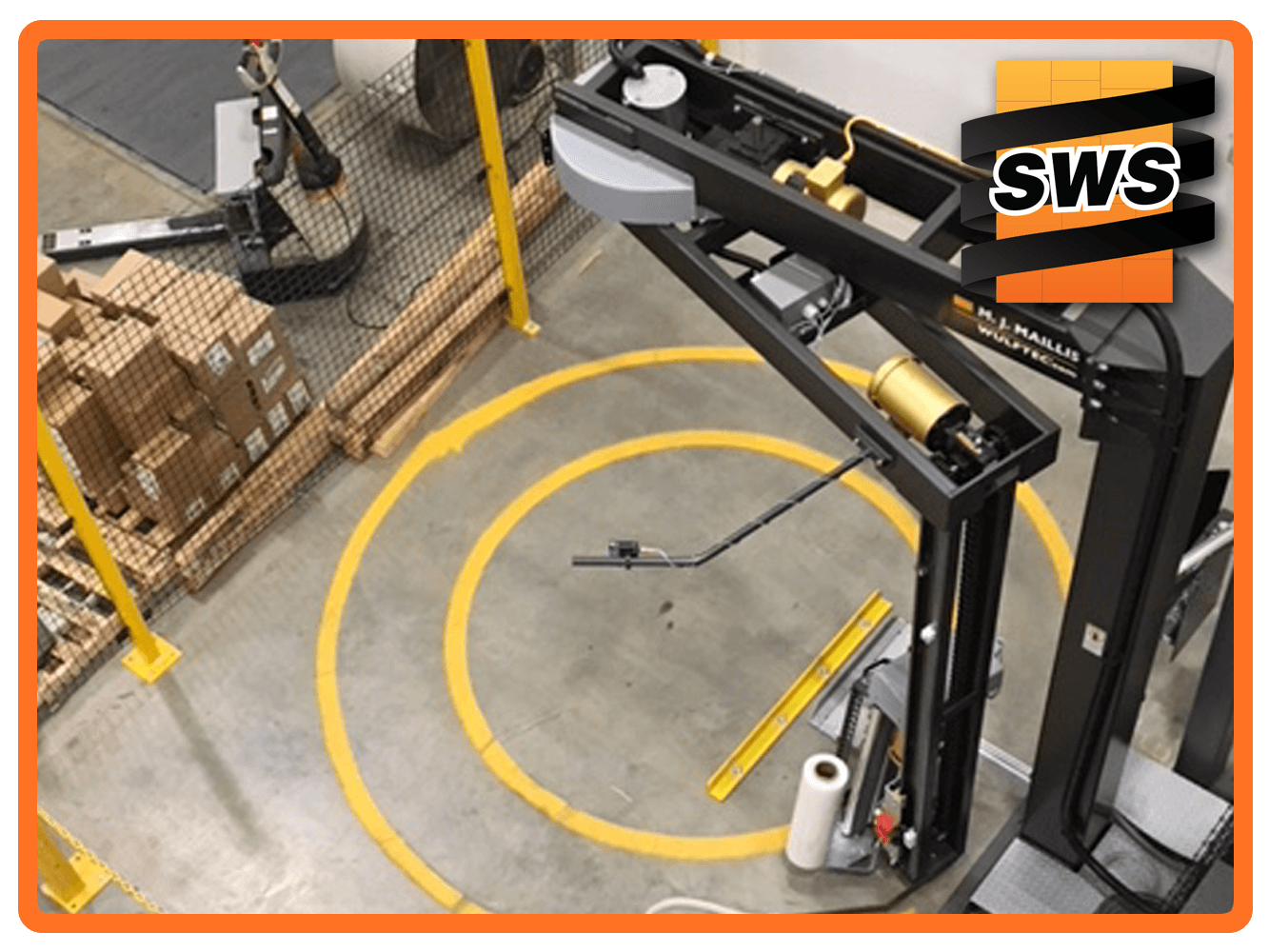

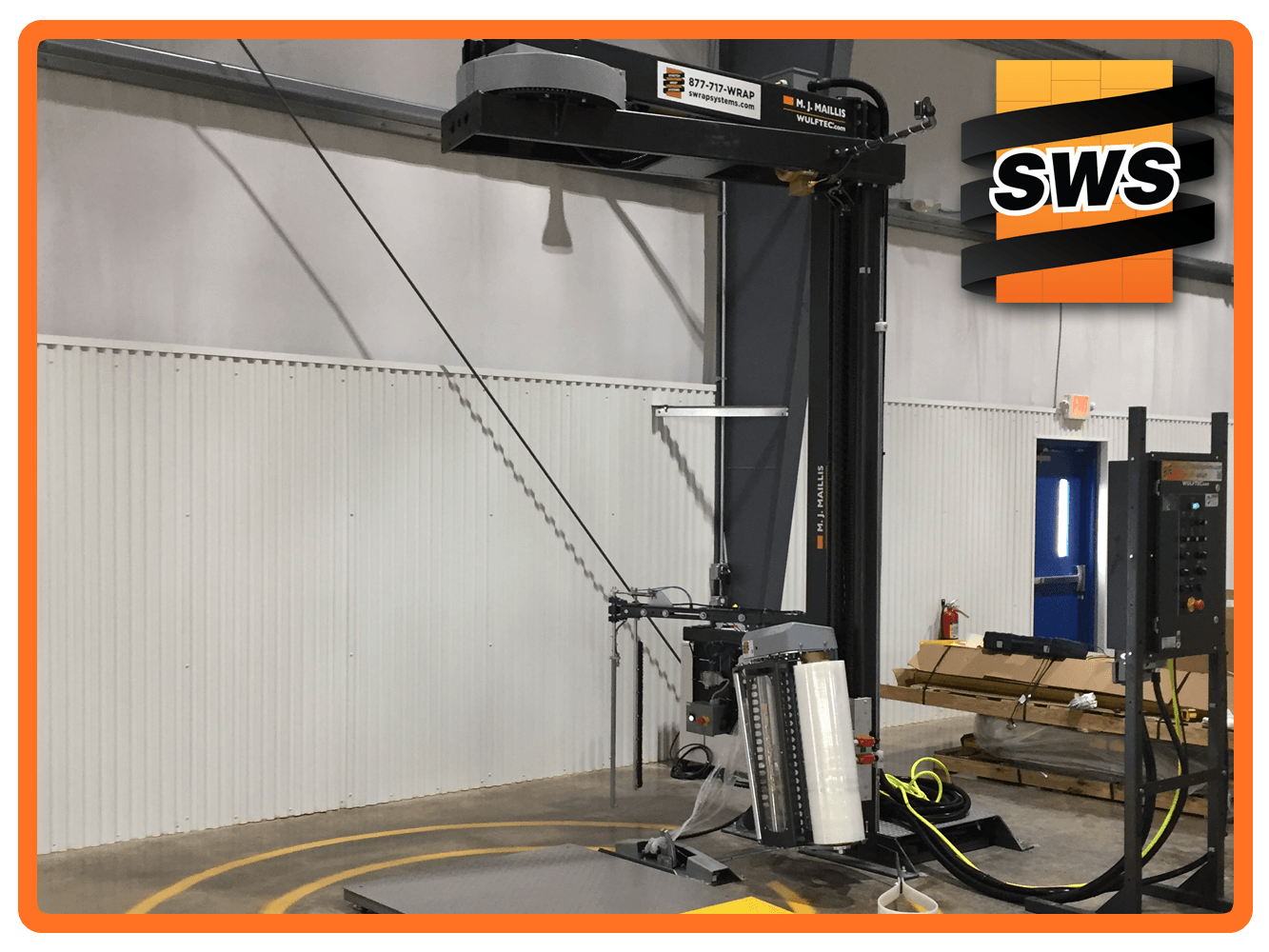

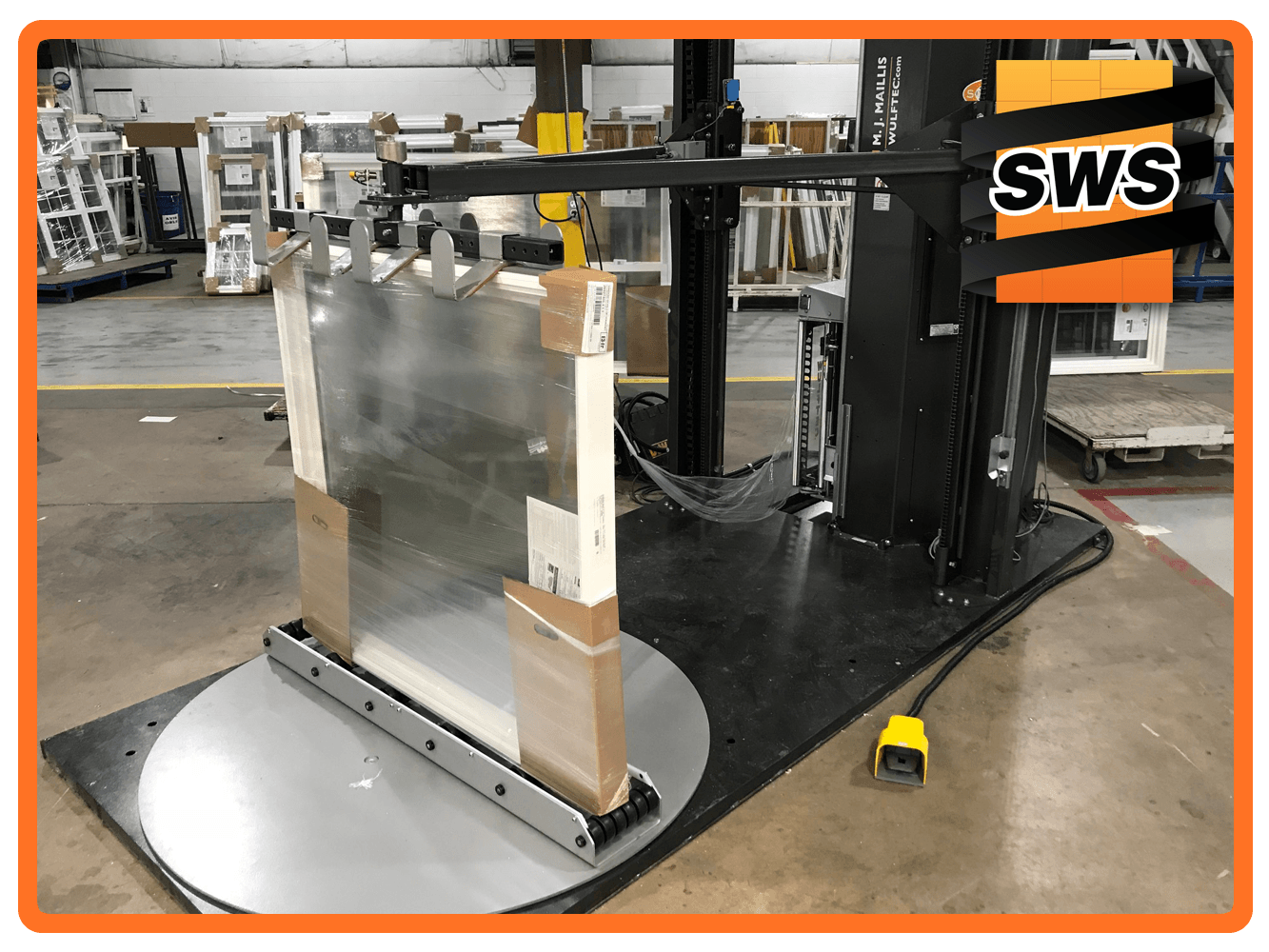

WCA-SMART Automatic Turntable Stretch Wrapper Furniture manufacturer Load centering device Load stabilizing top platen Safety photo eyes Lead Technician: Rich

Central PA – 3/17/18

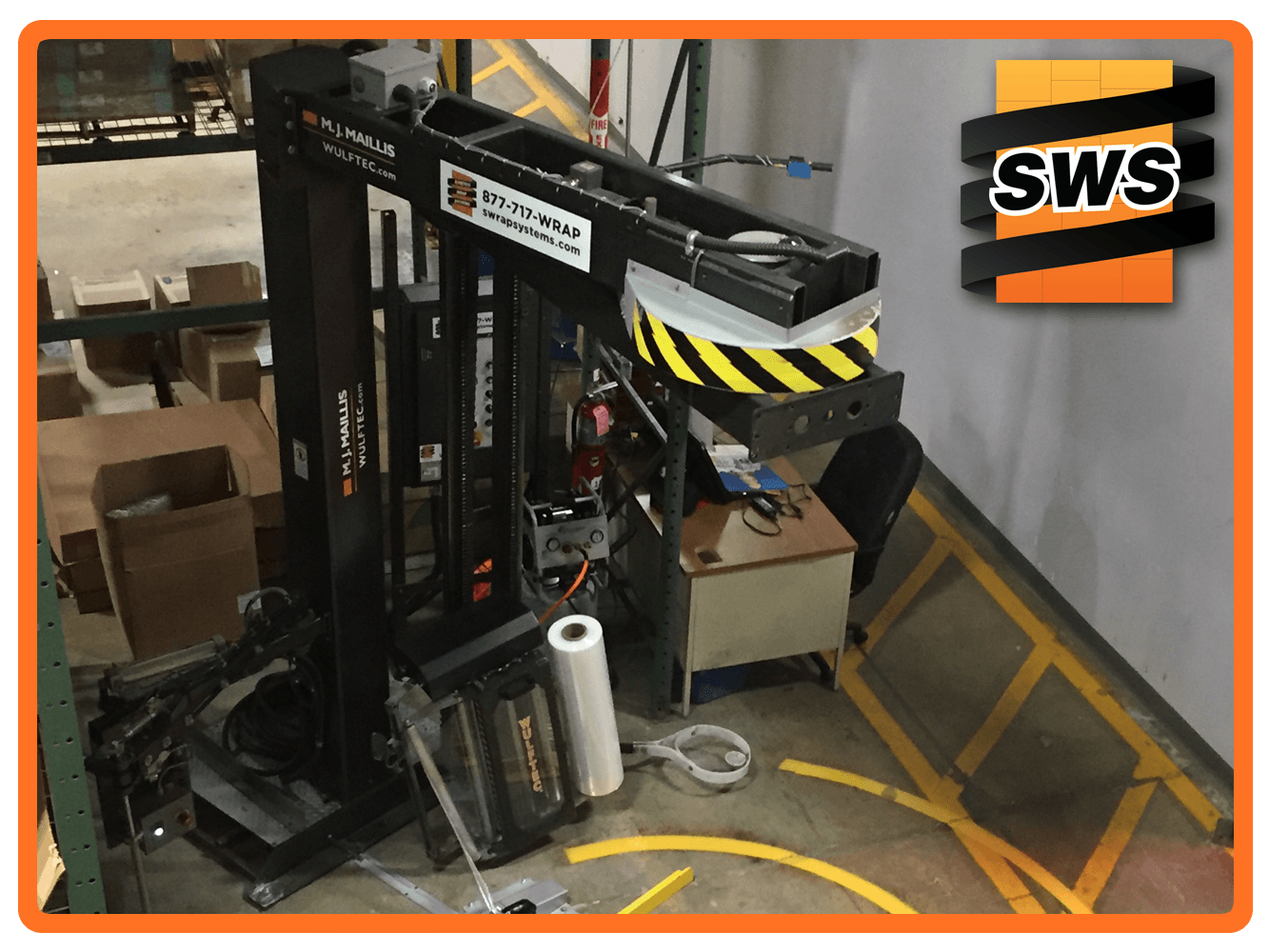

WCRT-175 Rotary Arm Stretch Wrapper Saturday installation 3 Strand Chain Conveyor Automatic cut wipe 30” Carriage Customer’s 3rd machine purchased! Technicians: John & Kyle

Bronx, NY – 3/16/18

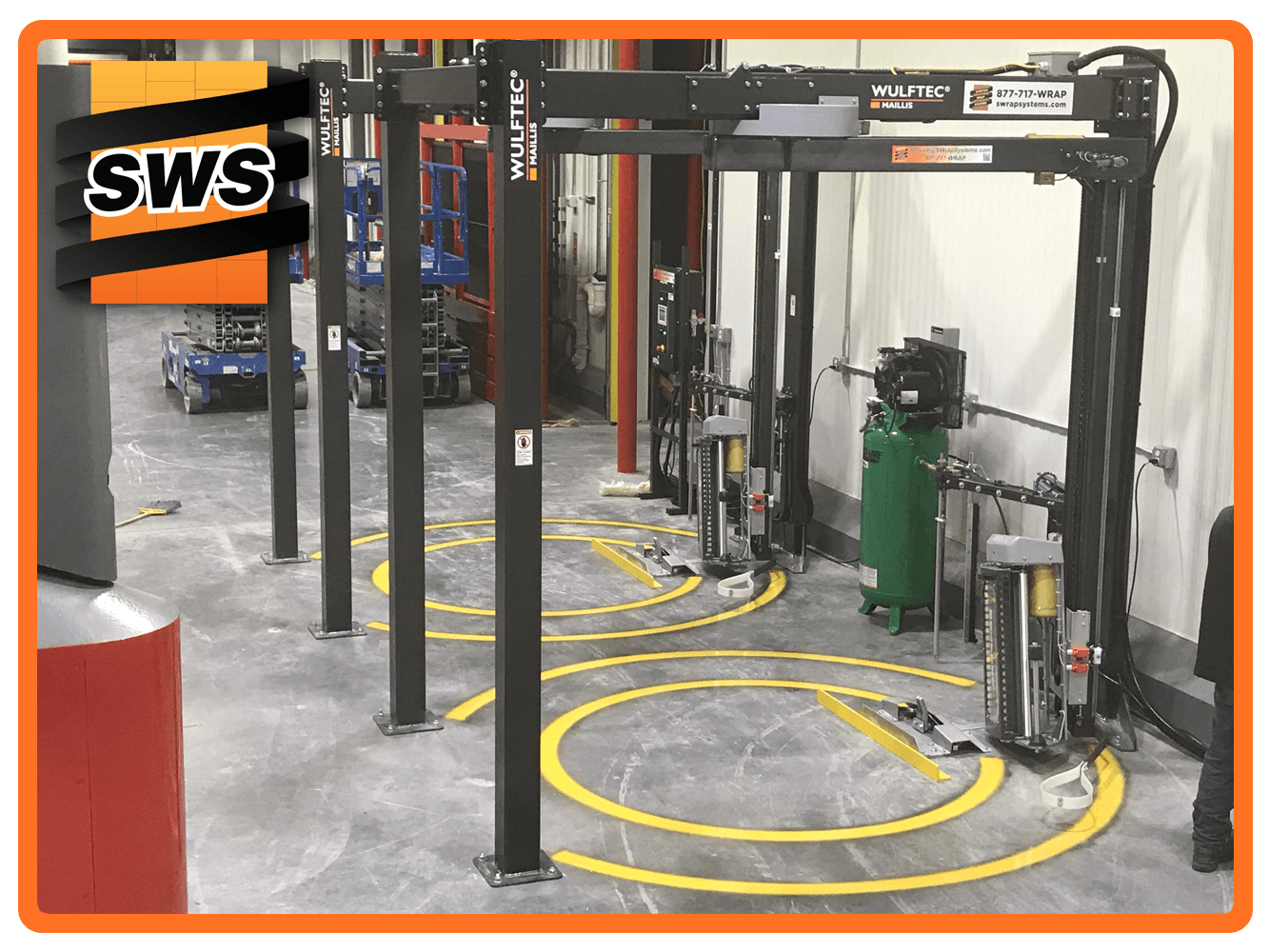

Wulftec WRTA-175 Rotary Arm Wrappers Food distributor Automatic cut wipe Panel view screen 12 RPM w/ 9 button lanyards 30″ carriage Installed side by side for use with double jack set up Technicians: Matt & Tiger

Buffalo, NY – 2/22/18

WCA-SMART Automatic Turntable Stretch Wrapper Wine producer 20″ carriage 16 RPM Automatic cut wipe In-line slipsheet dispenser Safety package with 3 light curtains Stand alone start/stop with emergency stop pedestal Technicians: Matt & Andrew

Philadelphia – 2/14/18

WRTA-150 Automatic Rotary Arm Wrapper Industrial materials Automatic cut wipe Panel view screen Technicians: Matt & Andrew

Central PA – 2/12/18

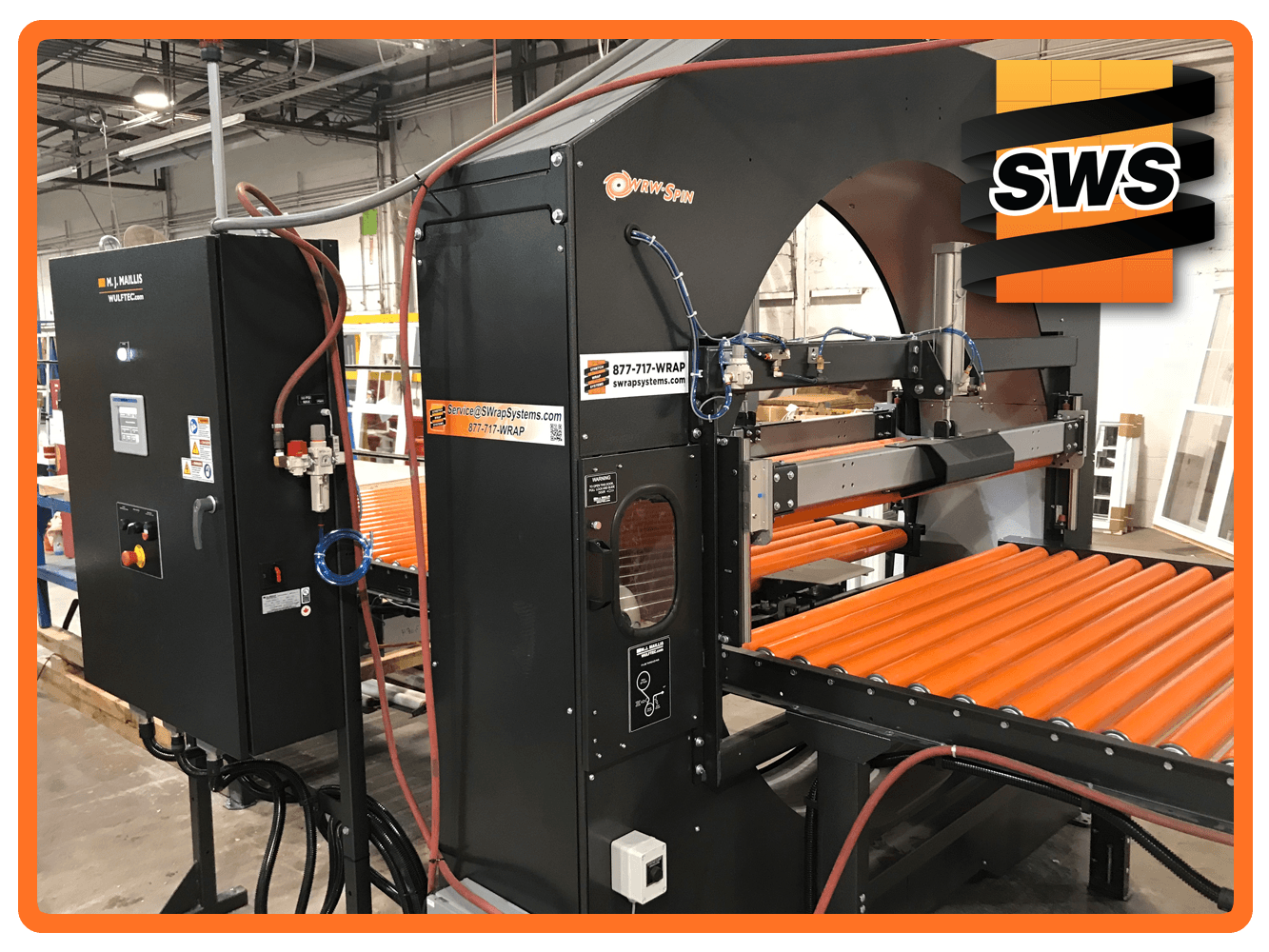

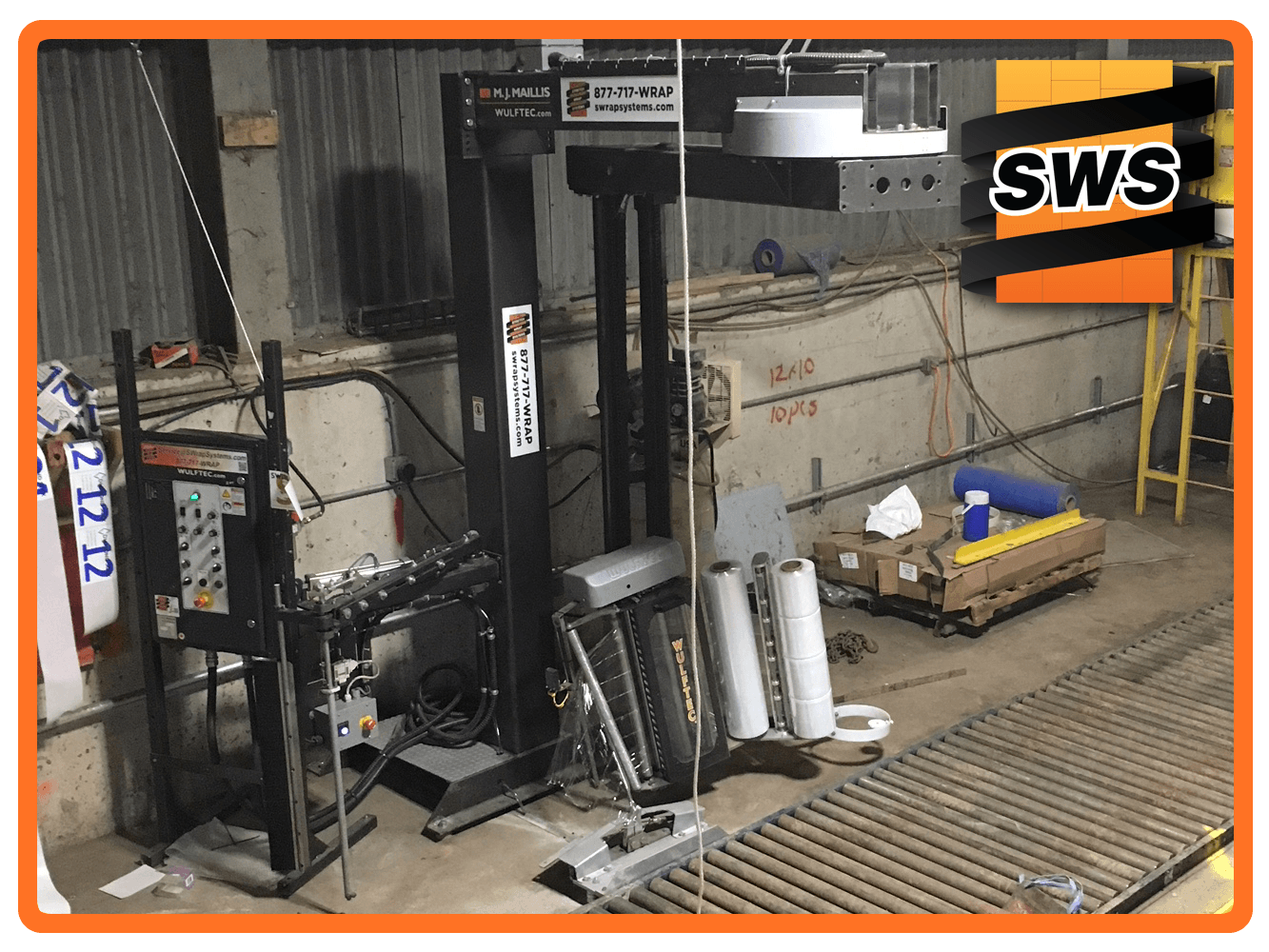

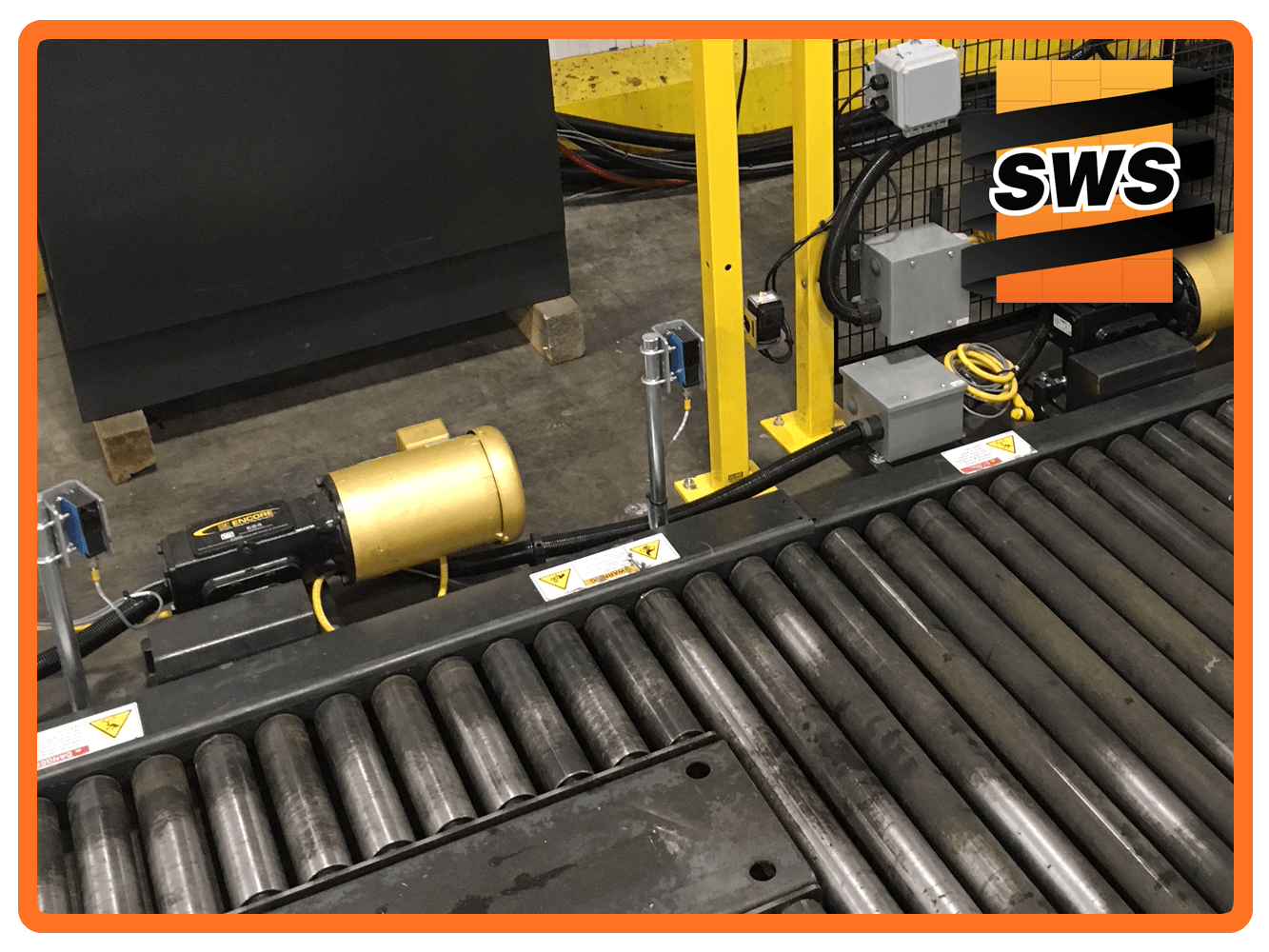

WRWA-200 Automatic Horizontal “Ring” Stretch Wrapper Window manufacturer Ring wrapper 10” carriage Custom coated conveyor rollers Panel view screen offers multiple wrap patterns for various window sizes Wrap pattern selector Technicians: Matt & John

Midstate, PA – 1/31/18

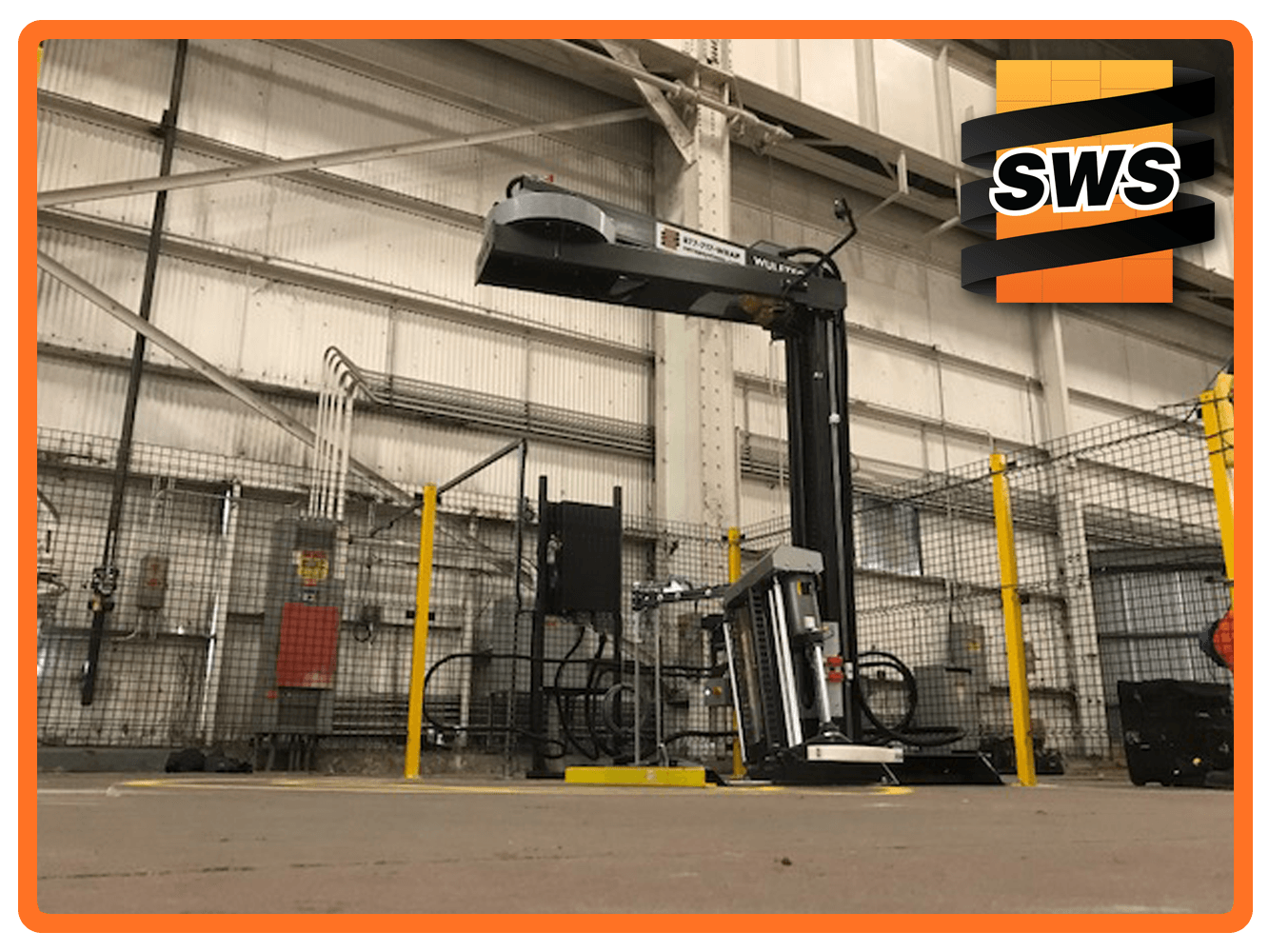

WRTA-200 Automatic Rotary Arm Wrapper Glass manufacturer Automatic cut wipe Light curtains Safety fencing Oversized wrap zone for wrapping 80″ pallets Customer’s 4th machine Technician: Rich

State College, PA – 1/26/18

WRTA-150 Automatic Rotary Arm Wrapper 30″ carriage Extended wrap height Automatic cut wipe Standard control panel Pull cord start 12 RPM Banding film Technician: Andrew

South Central, PA – 1/19/18

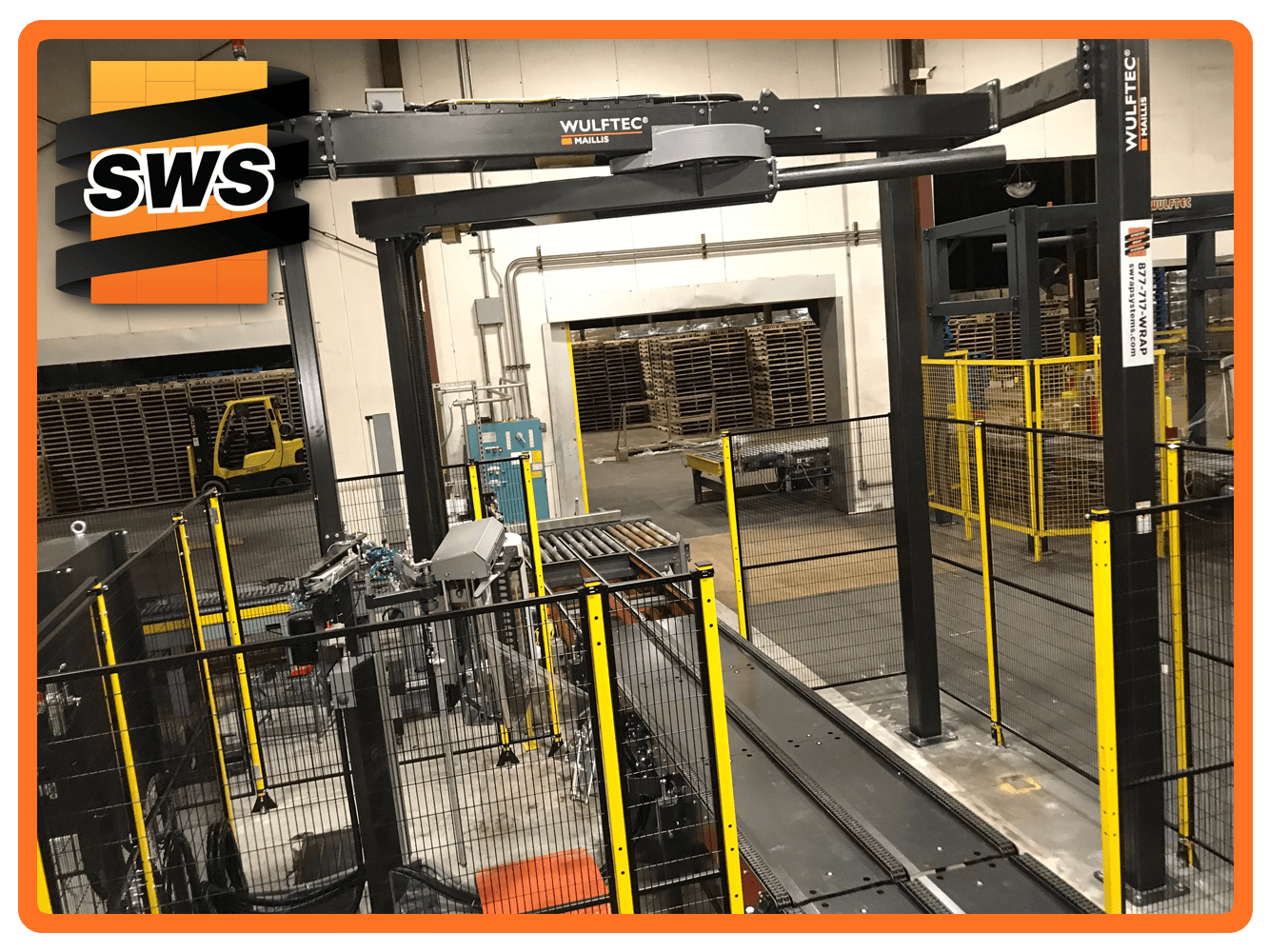

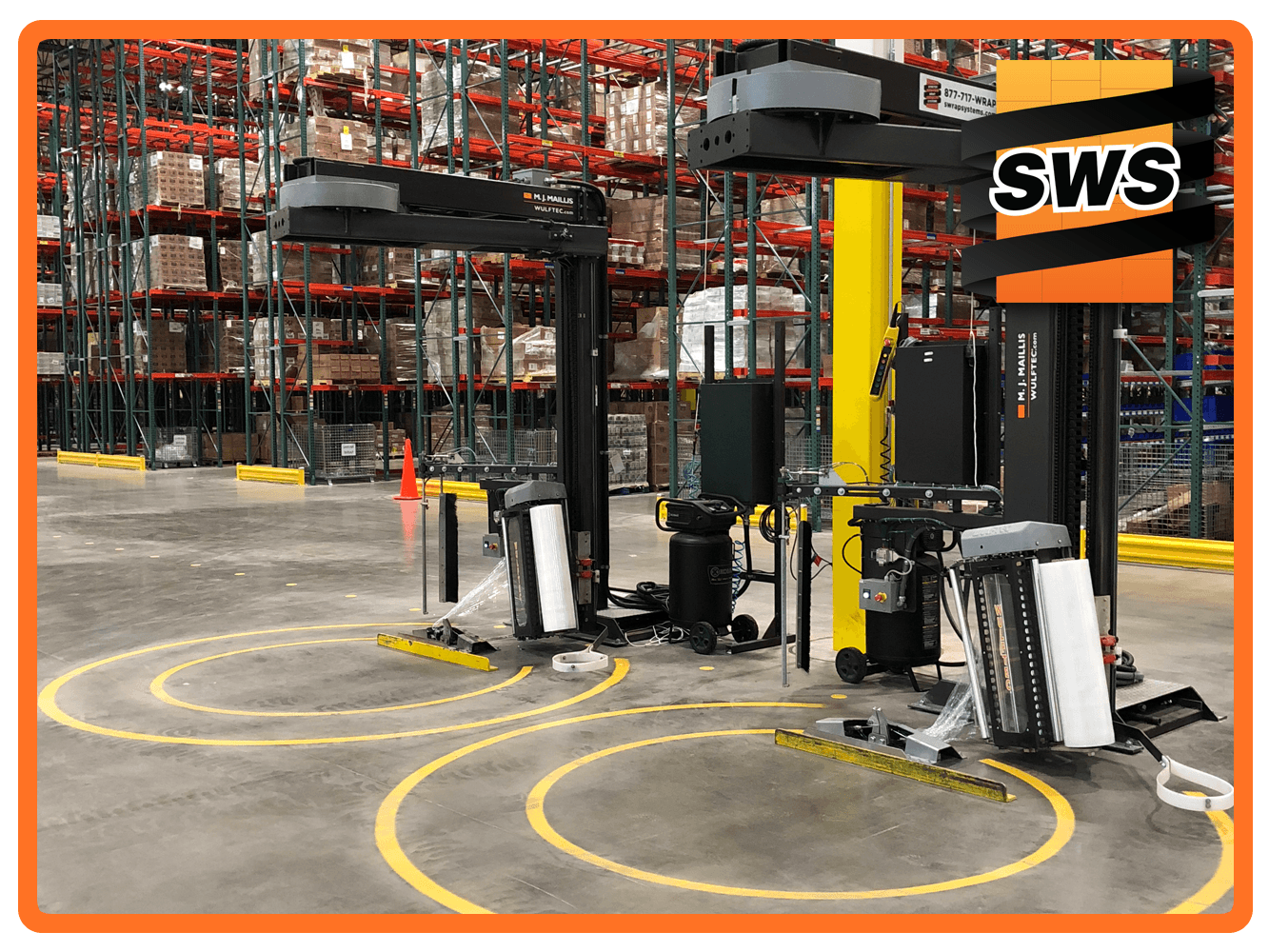

Wulftec WRTA-150 Rotary Arm Stretch Wrappers Shipping/Logistics 2 WRTA-150s 30″ carriages 80″ wrap height Automatic cut wipe Safety packages Wrap pattern selectors Technicians: Rich & Andrew

New Jersey – 1/18/18

WRTA-150 Rotary Arm Stretch Wrapper Cosmetics distributor Automatic cut wipe 30″ carriage Pull-cord start Technician: Kyle

Machine Relocation – 1/8/18

Wulftec WRTA-150 Rotary Arm Wrappers Beverage Distributor SWS technicians Matt and Tiger relocated this local beverage distributor’s two WRTA-150 stretch wrappers for tandem use within their facility. 30″ Carriages Automatic cut wipe Pull cord machine starts Technicians: Matt & Tiger

Kutztown, PA – 1/5/18

Wulftec WCA-SMART Automatic Turntable Stretch Wrapper Automatic cut wipe 20″ Carriage 16 RPM Technicians: Matt & Andrew

Central PA – 12/15/17

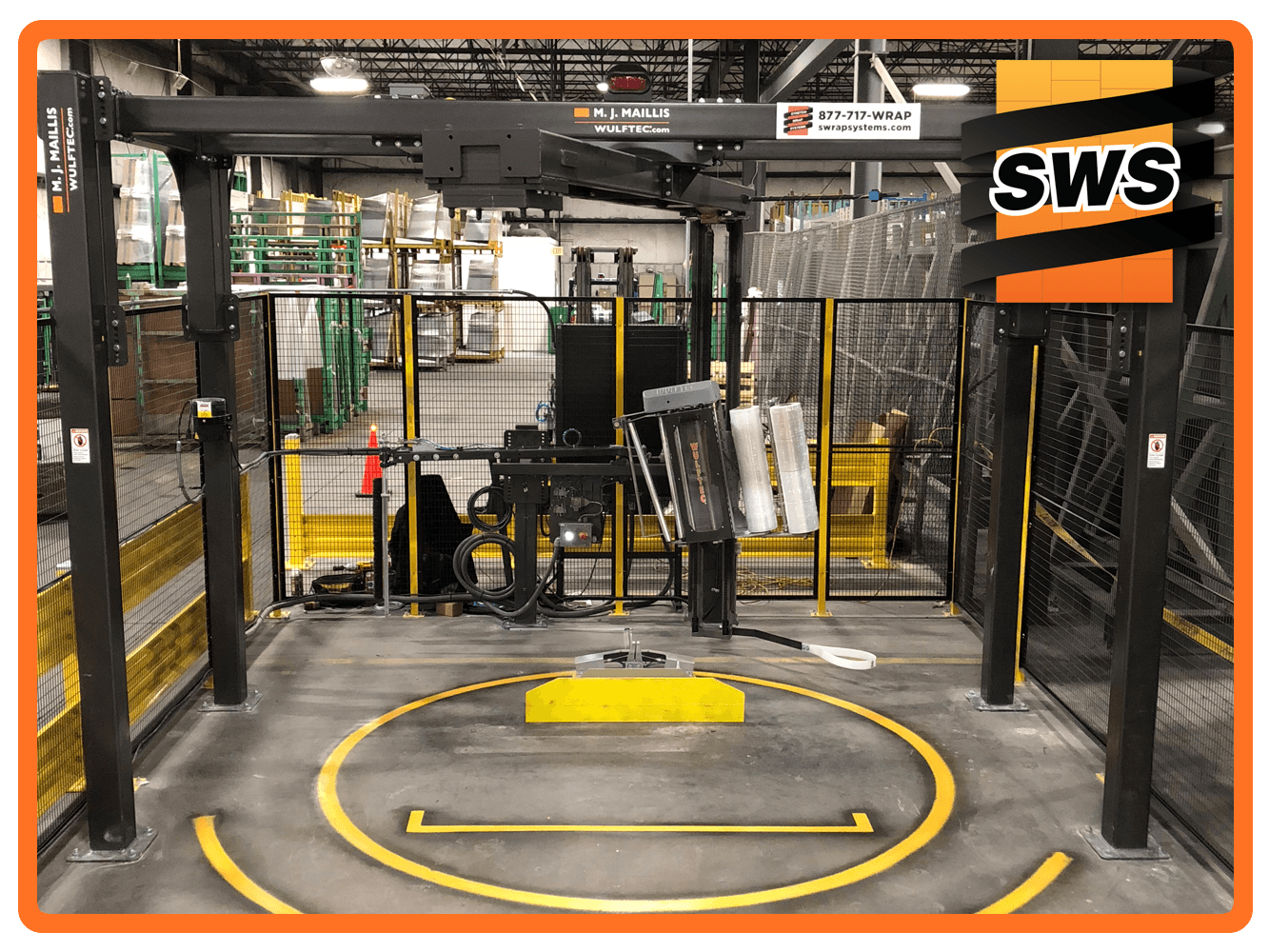

WRTA-200 Rotary Arm Wrapper CUSTOMERS 5th MACHINE! 30″ CARRIAGE LIGHT CURTAIN SYSTEM CUSTOM PANEL VIEW SCREEN 6 BUTTON LANYARD 116″ WRAP DIAM EXTENSION SAFETY FENCING LAZER POSITIONING SYSTEM DESIGNED BY S.W.S CUSTOM LOCK OUT DISCONNECT TECHNICIANS: Rich, Matt, Tiger

Paulsboro, NJ – 12/15/17

WCRT-200 Conveyorized Automatic Stretch Wrapper Automatic cut wipe 20″ carriage 24 RPM Light curtains Lead tech: Andrew

Bronx, NY – 12/8/17

Installation wrap zone photo-eye protection installed on a Wulftec WCRT-200 Lead tech: Andrew

S. Brunswick, NJ – 12/1/17

WRTA-150 Rotary Arm Wrapper Automatic cut wipe 30″ carriage Standard plus view panel 3 Pattern Lanyard Selector Extended wrap height Lead tech: Andrew

Pittsburgh – 12/1/17

WRTA-150 Automatic Rotary Arm Wrapper Health products distributor Automatic cut wipe 30″ carriage Lead tech: Kyle

Harrisburg, PA – 11/13/17

SMLPA-200 Automatic Turntable Wrapper Window manufacturer Automatic cut wipe Panel view screen offers multiple wrap patterns for various window sizes Lanyard selector 120 wrap height Lead tech: Matt

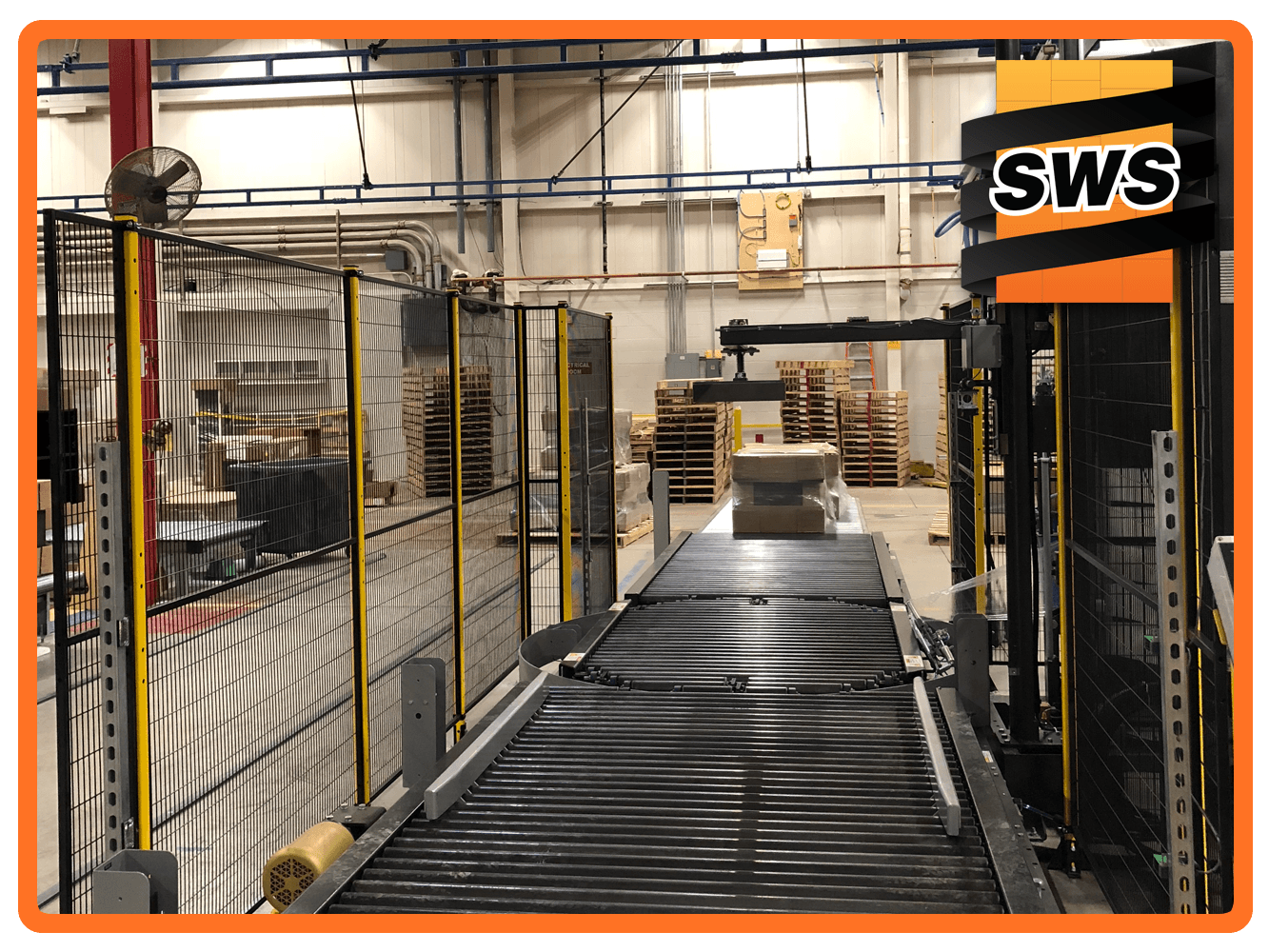

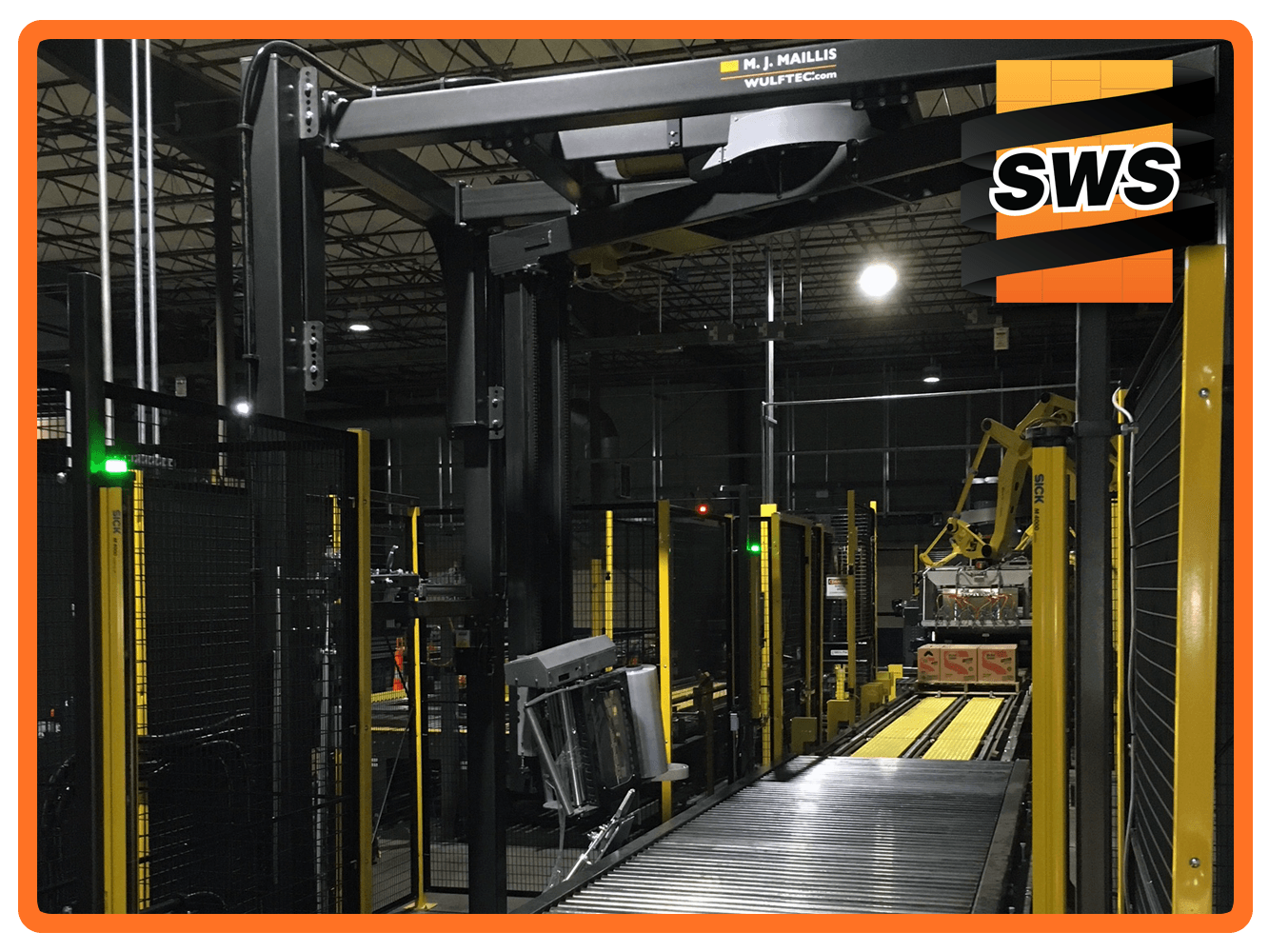

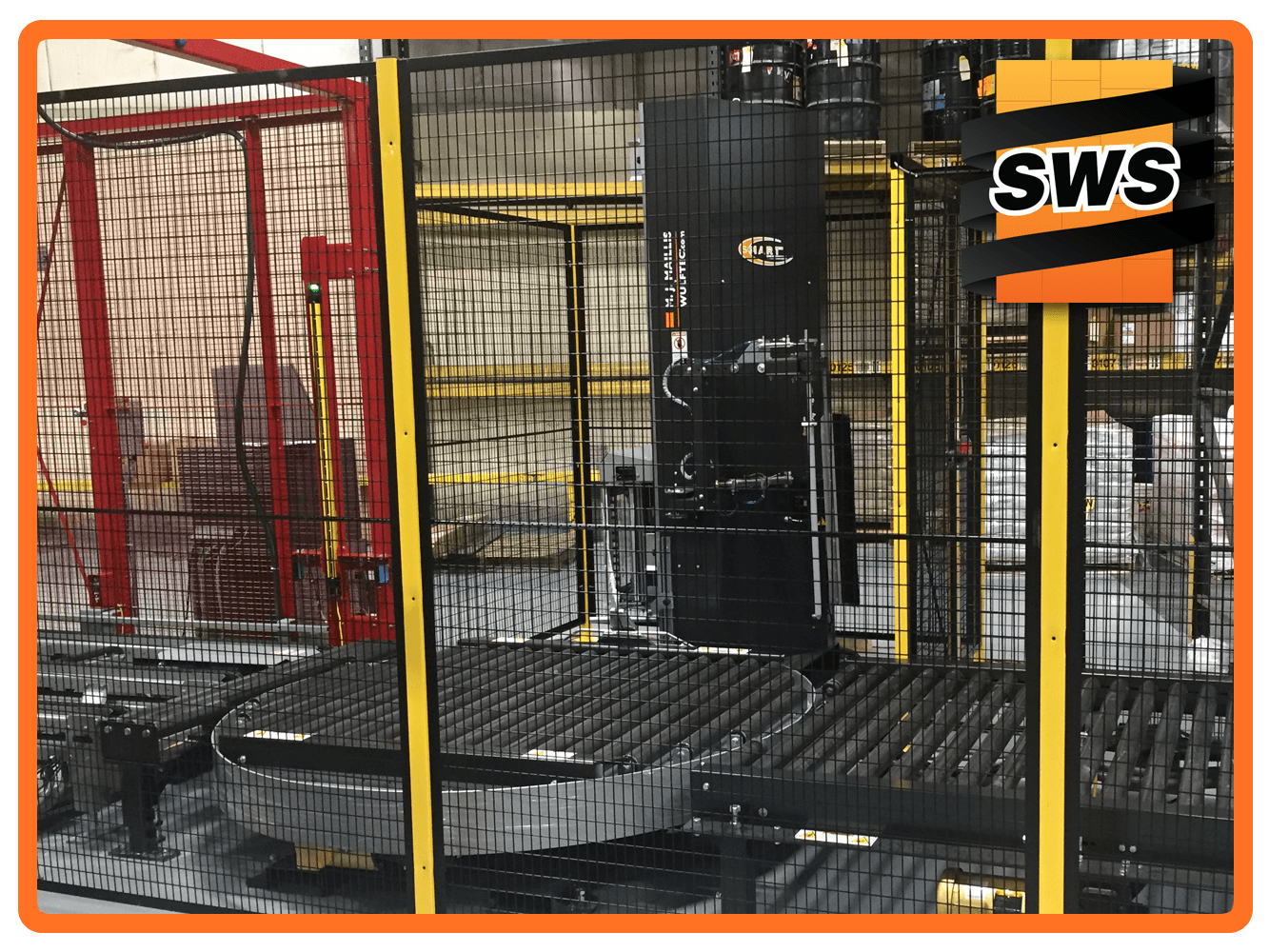

New York, NY – 11/2/17

Two Wulftec WCA-SMART Conveyorized Turntable Wrappers Two conveyorized turntable stretch wrappers 30″ carriages Automatic cut wipe Safety fencing Technician: Rich, Kyle, Matt & John